See product

See productOptical sorting in Agriculture

Optical sorting of Agriculture materials is very important not only for consumers but also for suppliers whose products are checked very rigorously in terms of quality.

How can you use optical sorting solutions?

Beans & pulses

Pulses crops are the second most important source of plant food in the world. Considering the sustainable production and increasing demand for these plants, we are improving the optical sorting technology in order to increase the efficiency, quality, and safety of the final products. With MEYER optical sorters, we get rid of various foreign bodies such as stones, glass, as well as rotten, infected, or discolored products. MEYER optical separators, by using various technologies, provide the possibility of thorough cleaning of various types of bean plants, from the smallest ones, such as lupins, through peas, to the largest varieties of beans.

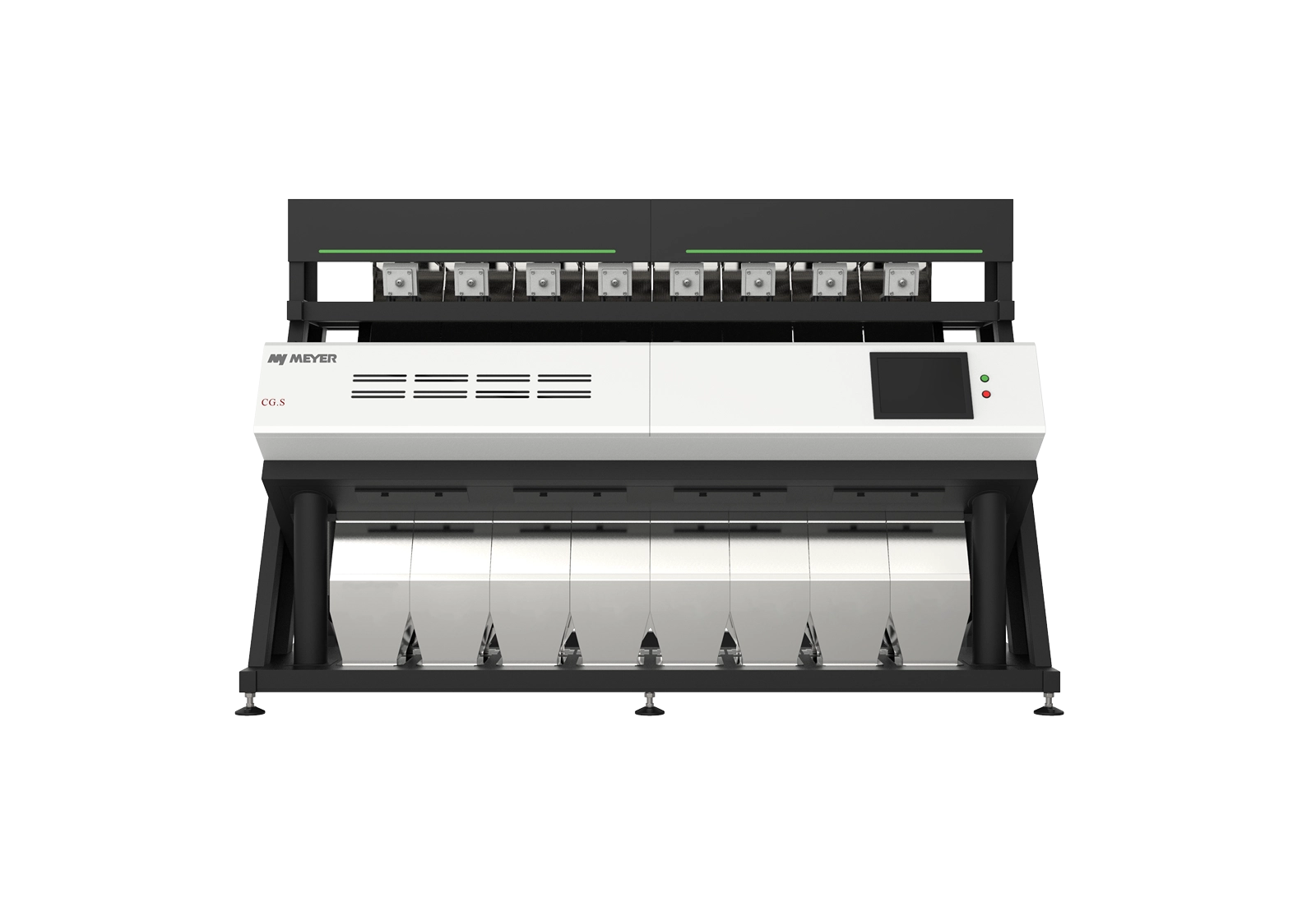

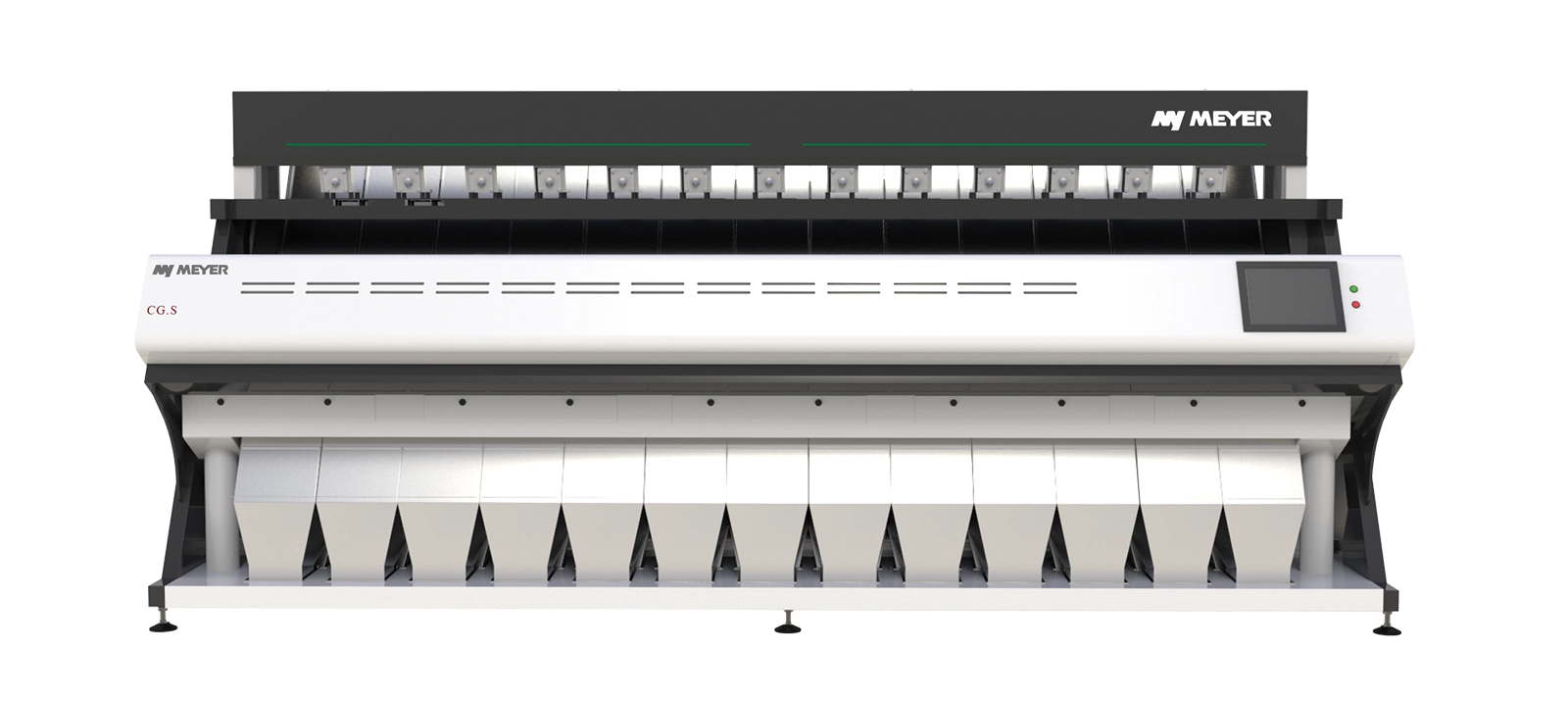

Beans & pulses sorting machines

Coffee

MEYER offers advanced solutions for sorting both green, raw coffee beans and roasted coffee. Using optical technology, defective beans—such as discolored, insect-damaged, immature, or over- and under-roasted beans—are effectively removed, ensuring uniformity and high quality in every batch. Additionally, MEYER X-ray detectors can identify foreign objects like stones, metal, or glass, even if they do not differ in color from the coffee beans. This system also operates on sealed packages, providing full control over product safety at every stage of production.

Coffee sorting machines

Fruits & vegetables

Optical sorting technology and X-ray detection are essential in fruit and vegetable processing, ensuring compliance with sanitary and epidemiological standards while achieving a pure final product. MEYER machines offer a wide range of applications that can be used for sorting fresh fruits and vegetables, as well as frozen, dried, or freeze-dried products. The use of MEYER optical sorters in fruit and vegetable processing guarantees increased production efficiency, reduces the need for human resources, and ensures consistency and high quality of the final product.

Fruits & vegetables sorting machines

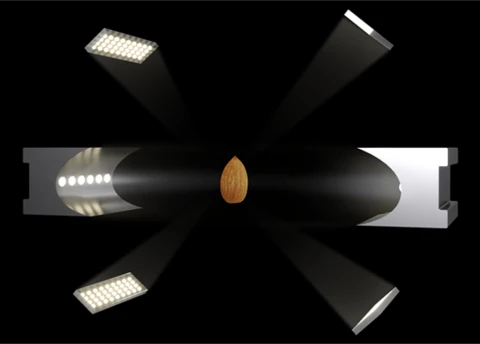

Nuts

MEYER offers a wide range of optical sorters for the separation and cleaning of various sizes, types, and forms of nuts: whole, halves, pieces, and in-shell nuts. Our solutions are used in the sorting of hazelnuts, peanuts, walnuts, macadamia, pecans, almonds, pistachios, cashews, and other species of nuts. The technologies used in MEYER machines allow obtaining detailed removal of shells, damaged, shrivelled and rotting products, as well as foreign materials such as sticks, grass, plastics, stones, metals, aflatoxins. MEYER offers both chutes and belt machines, therefore which we can protect the nuts from breaking during the manufacturing process.

Nuts sorting machines

Rice

Rice is one of the staple foods of the world. With continually improving living standards, rice quality requirements have steadily increased. Our company has been focused on rice sorting for 30 years. MEYER’s rice optical sorter can detect and remove mildewy, broken rice, and foreign materials like glass and stone and classify rice based on color, shape, and other differences. MEYER rice sorting solution provides efficient separation especially in extremely light yellow rice, rice with pin-points tips as well as diseased rice. MEYER’s dozens of customer solutions deliver great value to global customers. Also, it leads the technical innovation of the rice processing industry to make full use of each grain.

Rice sorting machines

Seeds & grains

Meyer offers a wide range of solutions for sorting seeds and grains, including wheat, corn, rye, barley, oat, buckwheat, millet, and many others. Our advanced sorting systems are tailored to meet individual customer needs, ensuring maximum efficiency and precision. The product range includes color sorters, sorters equipped with UV and InGaAs cameras, as well as X-ray detectors, enabling comprehensive quality control. By utilizing the latest technologies, our devices effectively detect and remove foreign objects, discolored, damaged grains, and those contaminated with aflatoxins. The wide selection of available solutions allows for precise cleaning and selection of materials.

Seeds & grains sorting machines

Spices

Optical sorting of spices such as dried parsley, dill, freeze-dried chives, marjoram, oregano, and basil requires precise solutions tailored to lightweight materials. MEYER offers advanced machines that effectively eliminate impurities and unwanted fractions, ensuring the highest quality of the final product. With cutting-edge technology and the extensive expertise of our specialists, each solution is customized to the specific characteristics of the sorted raw material. Our systems enable precise recognition of differences in color, shape, and texture, ensuring reliability and consistency throughout the sorting process.

Sorting SpicesSpices sorting machines

Tea

Sorting tea and other delicate materials, such as hibiscus, nettle, or mint leaves, requires precise tools and specialized knowledge. With years of experience and advanced technological solutions, MEYER offers machines that effectively classify tea leaves based on their color, shape, and other distinctive characteristics. The optical sorters are also capable of detecting and removing contaminants such as sticks, insects, and damaged or discolored leaves and stems.

Sorting TeaTea sorting machines

Canned & bottled food

MEYER X-RAY inspection machine provides customers with intelligent, professional, and comprehensive inspection solutions in many areas of the food industry. Technologies used in X-RAY devices ensure the safety and quality of food products. MEYER offers X-RAY detectors that make it possible to detect foreign bodies in canned, bottled, or boxed food and other packages. Using MEYER X-RAY machines, various foreign bodies, such as metals, stones, glass, lumps of earth, rubber, Teflon elements, plastics, or raw bones may be recognized in products.

Canned & bottled food sorting machines

Fruits & vegetables

Optical sorting technology and X-ray detection are essential in fruit and vegetable processing, ensuring compliance with sanitary and epidemiological standards while achieving a pure final product. MEYER machines offer a wide range of applications that can be used for sorting fresh fruits and vegetables, as well as frozen, dried, or freeze-dried products. The use of MEYER optical sorters in fruit and vegetable processing guarantees increased production efficiency, reduces the need for human resources, and ensures consistency and high quality of the final product.

Fruits & vegetables sorting machines

Meat & seafood

Sorting meat and seafood with X-RAY detectors is a revolutionary technology that ensures the highest standards of food safety and quality. MEYER machines precisely detect and eliminate all foreign objects – from metals, glass, and plastic to hard-to-spot contaminants such as bone fragments, cartilage, and shell pieces. For seafood, our MEYER X-RAY detectors effectively identify hidden foreign objects even within closed shells. For the meat industry, MEYER X-RAY technology detects animal bone residues, cartilage, and other contaminants, eliminating the risk of their presence in final products.

Sorting Meat & seafoodMeat & seafood sorting machines

Nuts

MEYER offers a wide range of optical sorters for the separation and cleaning of various sizes, types, and forms of nuts: whole, halves, pieces, and in-shell nuts. Our solutions are used in the sorting of hazelnuts, peanuts, walnuts, macadamia, pecans, almonds, pistachios, cashews, and other species of nuts. The technologies used in MEYER machines allow obtaining detailed removal of shells, damaged, shrivelled and rotting products, as well as foreign materials such as sticks, grass, plastics, stones, metals, aflatoxins. MEYER offers both chutes and belt machines, therefore which we can protect the nuts from breaking during the manufacturing process.

Nuts sorting machines

Packed food

Detection of foreign objects and sorting of packaged food using MEYER X-RAY detectors is an excellent solution that ensures the highest level of quality control on the production line. This technology enables the detection of contaminants in sealed packages, guaranteeing that products containing unwanted foreign objects do not reach consumers. MEYER machines precisely detect metals, glass, plastic, stones, and other contaminants, even in tightly sealed packages, ensuring complete safety and product quality. This reliable quality control tool eliminates the risk of defective products at every stage of production, ensuring customer satisfaction and safety.

Sorting Packed foodPacked food sorting machines

Rice

Rice is one of the staple foods of the world. With continually improving living standards, rice quality requirements have steadily increased. Our company has been focused on rice sorting for 30 years. MEYER’s rice optical sorter can detect and remove mildewy, broken rice, and foreign materials like glass and stone and classify rice based on color, shape, and other differences. MEYER rice sorting solution provides efficient separation especially in extremely light yellow rice, rice with pin-points tips as well as diseased rice. MEYER’s dozens of customer solutions deliver great value to global customers. Also, it leads the technical innovation of the rice processing industry to make full use of each grain.

Rice sorting machines

Spices

Optical sorting of spices such as dried parsley, dill, freeze-dried chives, marjoram, oregano, and basil requires precise solutions tailored to lightweight materials. MEYER offers advanced machines that effectively eliminate impurities and unwanted fractions, ensuring the highest quality of the final product. With cutting-edge technology and the extensive expertise of our specialists, each solution is customized to the specific characteristics of the sorted raw material. Our systems enable precise recognition of differences in color, shape, and texture, ensuring reliability and consistency throughout the sorting process.

Sorting SpicesSpices sorting machines

Glass

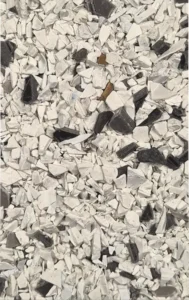

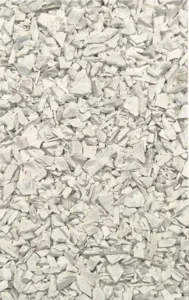

Glass consumption worldwide is continuously increasing. More and more countries are implementing regulations that require the processing of glass materials to recover valuable resources, benefiting the environment and reducing waste. The glass sorting process involves technology that removes all types of impurities (stones, metals, plastics, etc.) from the glass fraction. Separation is crucial for high-quality recycling, as it eliminates contaminants and improves the purity of the recovered glass. Glass sorting can also include the division into different color fractions, making it possible to obtain clean and homogeneous materials that are more valuable in the recycling process. This division not only improves the appearance of the final products but also enhances their quality, as glass of a specific color can be reused in the production of new packaging or other glass products with specific color requirements.

Sorting GlassGlass sorting machines

HDPE

Optical and polymer sorting of HDPE are methods that use advanced optical technologies and infrared cameras to precisely separate high-density polyethylene (HDPE) from other materials. Thanks to the appropriately selected cameras, sorting systems can quickly identify HDPE, even in complex waste streams. Recycling becomes faster, more precise, and cost-effective, contributing to more efficient waste management and improving the profitability of the recycling process.

HDPE sorting machines

Metal

The optical sorting process in metal processing aims to precisely separate metals from other materials, such as cables, plastics, or production waste. Metals, being high-value resources, require special attention during sorting to ensure the highest quality of the recovered material and minimize the amount of rejected material. This process allows for the accurate differentiation of various types of metals, such as copper, brass, aluminum, or stainless steel, significantly increasing recycling efficiency. Optical sorting also enables the removal of contaminants, contributing to the purity of the recovered metal, making it ready for reuse in industry. Modern MEYER sorters can process several tons of input material per hour, making the recycling process fast, efficient, and environmentally friendly.

Metal sorting machines

PET

Optical PET sorting with MEYER machines is a process that allows for the precise separation of valuable materials from contaminants. Thanks to advanced optical technology, our devices accurately identify and separate PET flakes, ensuring the highest quality of recovered materials. MEYER optical sorters operate based on color and polymer detection, enabling effective separation of different types of plastics, including PET, PVC, HDPE, and PP. This technology ensures not only high precision but also process speed, increasing the efficiency and profitability of recycling. Our solutions enable more eco-friendly and cost-effective material recovery, supporting the sustainable development of the recycling industry.

PET sorting machines

Plastic

MEYER is a leading manufacturer of optical and color sorters for the recycling industry. We care about the environment and increase the recovery of recyclable materials from waste, therefore we introduce various technological solutions to the recycling market. We offer devices for the optical separation of bottles, granules, regrinds of plastics, both in terms of color and polymer (including PET, PVC, HDPE, PP, PC, etc.). MEYER solutions allow customers to accurately separate valuable material from impurities, separate colors and polymers. We pay particular attention to the precision and speed of the process in order to achieve the maximum value from products. The solutions we offer are the highest quality color and polymer optical sorters designed by engineers and researchers from the high technology industry. The optical sorting system for plastics consists of selecting the right device and designing the entire sorting system. At MEYER, specialists and engineers with many years of experience and understanding of the optical sorting and recycling industries do this.

Sorting PlasticPlastic sorting machines

PP

The polypropylene (PP) optical and polymer sorting process is a method that utilizes advanced detection technologies to precisely separate PP from other materials (including different types of plastics, foreign bodies, and various contaminants). By using specialized cameras, sorting systems quickly identify the unique optical characteristics of polypropylene and use this information to classify the material fractions. This process not only improves the quality of the recovered material but also enhances the efficiency of the entire recycling process, enabling faster processing and cost optimization.

Sorting PPPP sorting machines

PVC

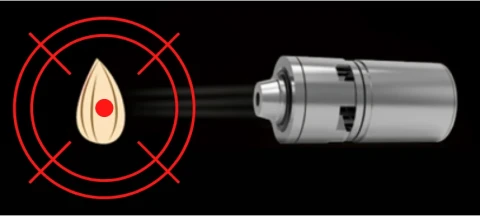

PVC sorting involves separating polyvinyl chloride (PVC) from other materials and contaminants. The sorting process with MEYER technology relies on the air jet system to eject materials. The system detects contaminants and defective materials in the waste stream, then expels them using specialized MEYER Maglev ejectors. The sorting process can be based on differences in the material's color or type (polymer differences), allowing for precise separation of the desired fractions from the rest.

PVC sorting machines

Rubber

Rubber sorting is a process that involves separating rubber waste for reuse in various industries. It can include both natural and synthetic rubbers, such as butyl rubber, neoprene rubber, and vulcanized rubber. Rubber sorting is a crucial stage in recycling as it allows for the separation of rubber from other materials like plastic and metal, enabling the recovery of high-quality raw materials for further processing. Modern technologies, including optical sorting, can assist in the precise identification of rubber materials, which enhances process efficiency and reduces contamination. Recycled rubber can be used in the production of new tires, mats, floor coverings, and other industrial applications.

Sorting RubberRubber sorting machines

Samples of sorting materials in Agriculture

Benefits of using optical sorting in Agriculture

Increased purity and quality

Optical sorters can detect and remove discolored materials, foreign materials, and defects such as stones, sticks, or damaged grains. This results in higher purity and quality of the final product, meeting consumer and market standards.

Better Efficiency and Throughput

Optical sorting technology allows for the processing of large volumes of quickly and accurately, significantly improving throughput compared to manual sorting methods.

Reduced Labor Costs

Automated sorting reduces the need for manual labor, leading to cost savings and reduced human error in the sorting process.

Improved Product Value

Higher quality and purity of sorted can lead to better market prices and customer satisfaction.

Versatility and Flexibility

Optical sorters can be used for different varieties of and can be adjusted for different sorting needs, making them versatile tools in processing.

Reduced Waste

Efficient sorting helps reduce waste by ensuring that only genuinely defective materials are removed, while maximizing the amount of good product.

Data Collection and Analysis

Modern optical sorting systems can collect valuable data about the waste stream, such as composition and contamination levels, aiding in process optimization and regulatory compliance.

Decreased Environmental Impact

By increasing the amount and quality of recycled materials, optical sorters contribute to reduced reliance on virgin resources, lower greenhouse gas emissions, and a smaller environmental footprint for waste management operations.

Enhanced Product Safety

By removing contaminated grains or foreign objects, optical sorters help prevent potential health hazards, contributing to safer products.

What type of sorter do you need?

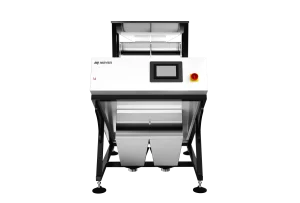

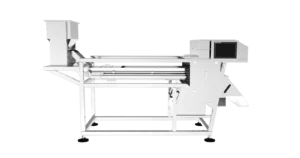

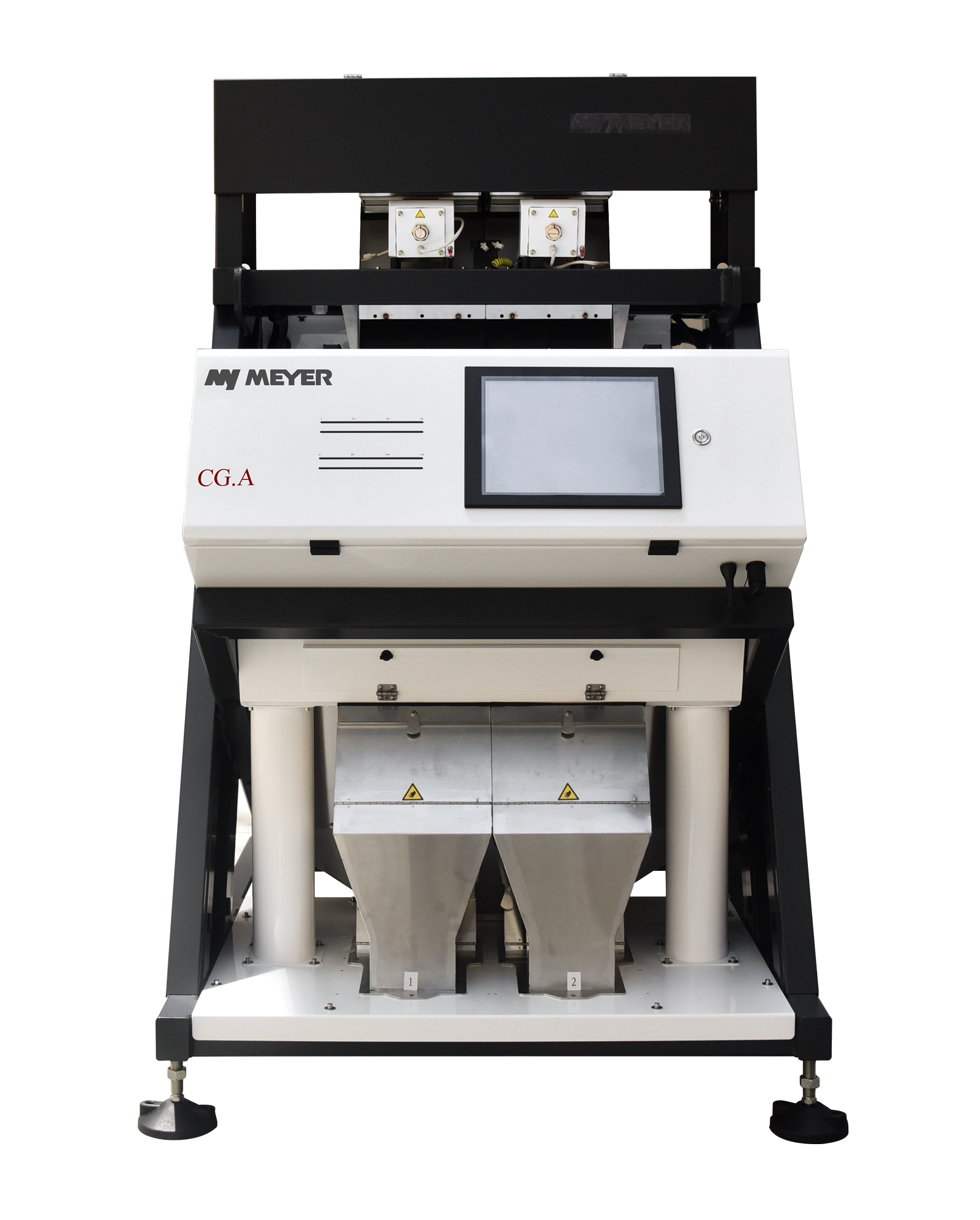

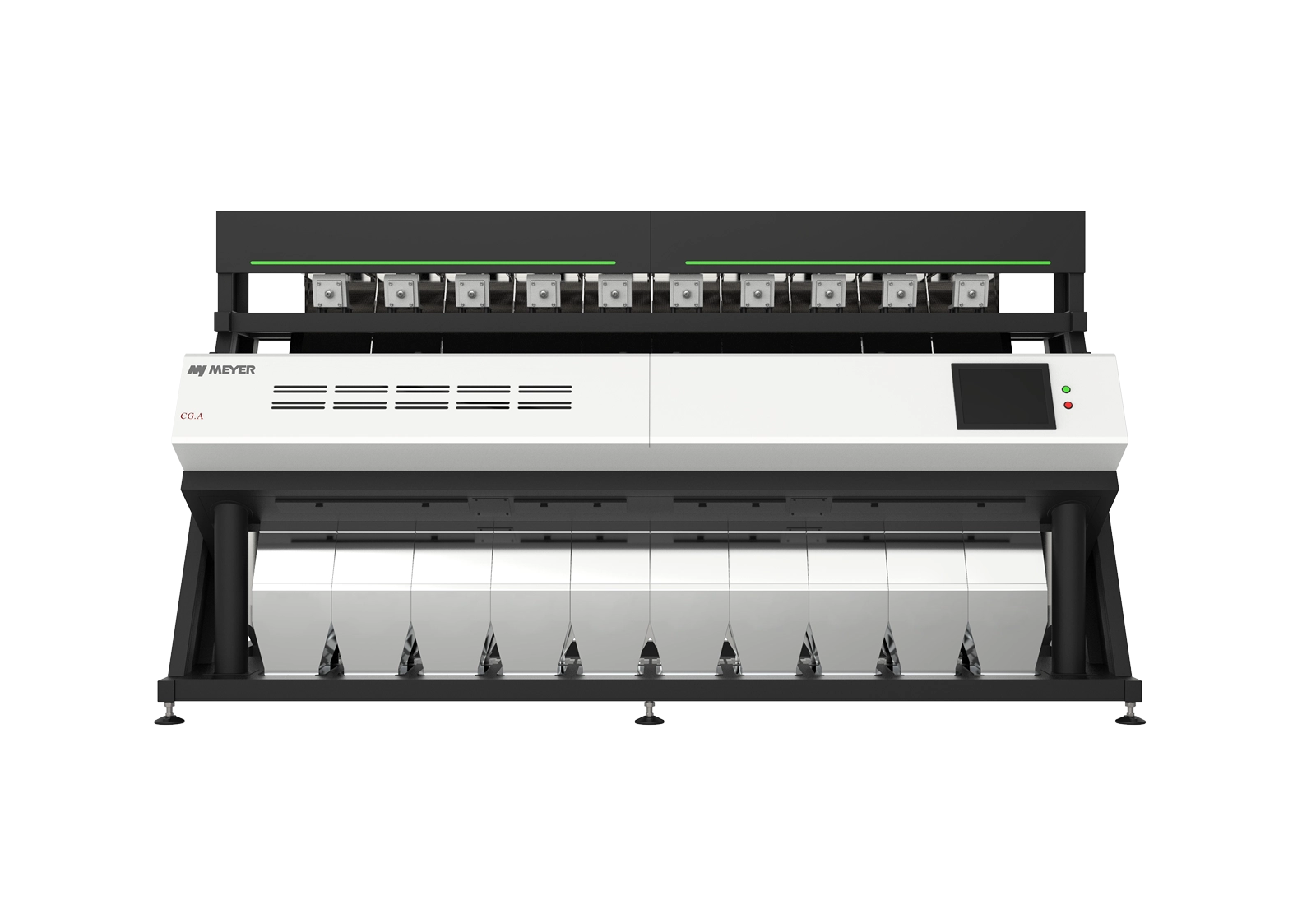

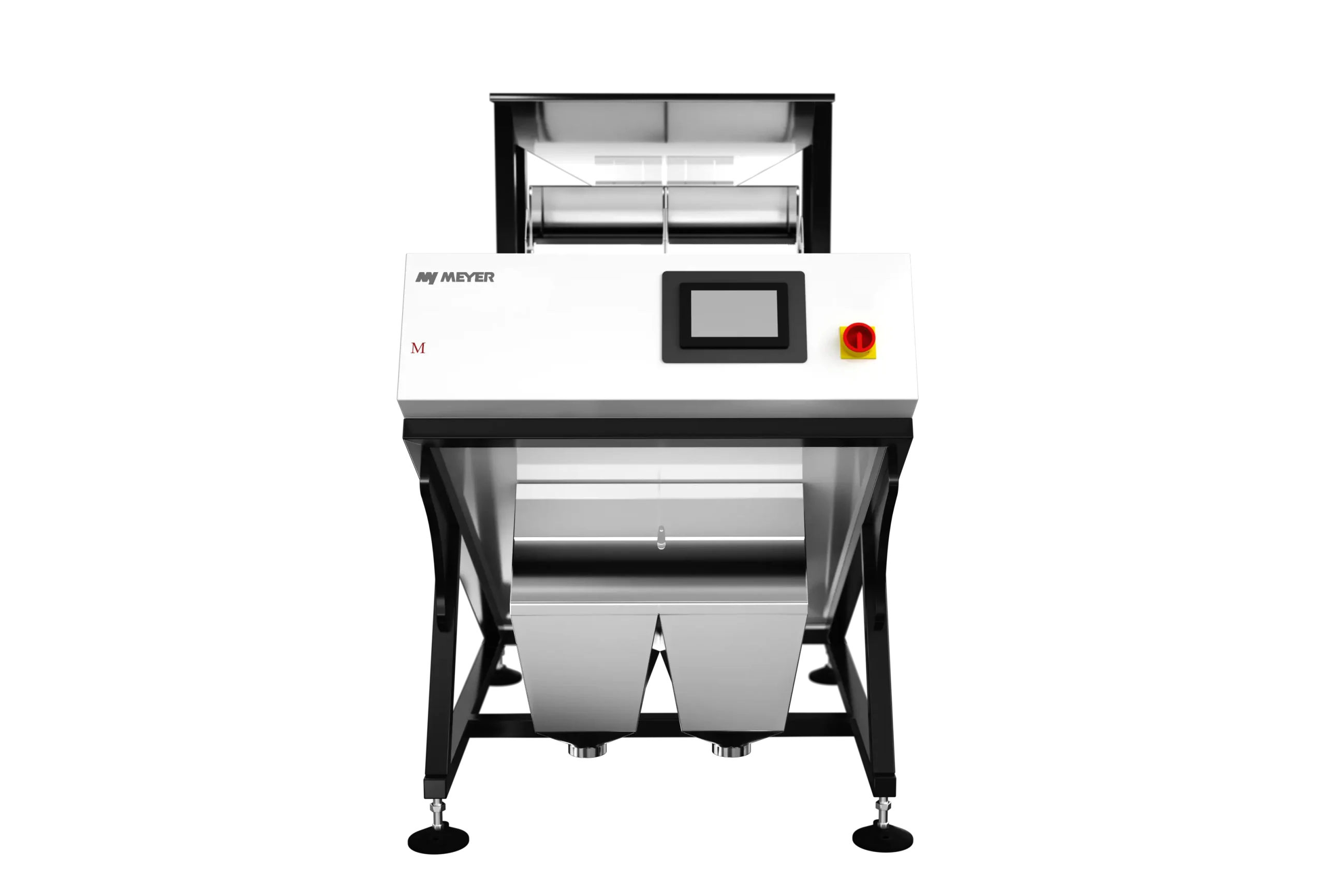

Chute color sorters

Our chute color sorters are a versatile solution, ideal for the recycling industry and the food and agricultural sectors. In recycling, they efficiently separate plastic fractions, glass, and metals by color, increasing material value and facilitating further processing. In the food and agricultural industries, they excel at sorting grains, seeds, nuts, spices, and dried fruits, removing impurities and unwanted fractions. Precise color separation enhances efficiency, improves raw material quality, and reduces waste. With advanced optical technologies and AI Deep Learning systems, our sorters ensure reliability and efficiency, meeting the demands of even the most challenging production and recycling processes.

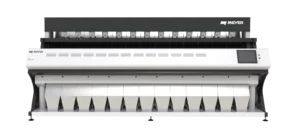

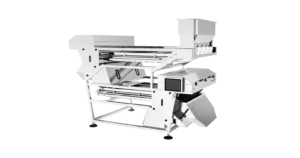

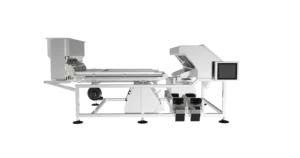

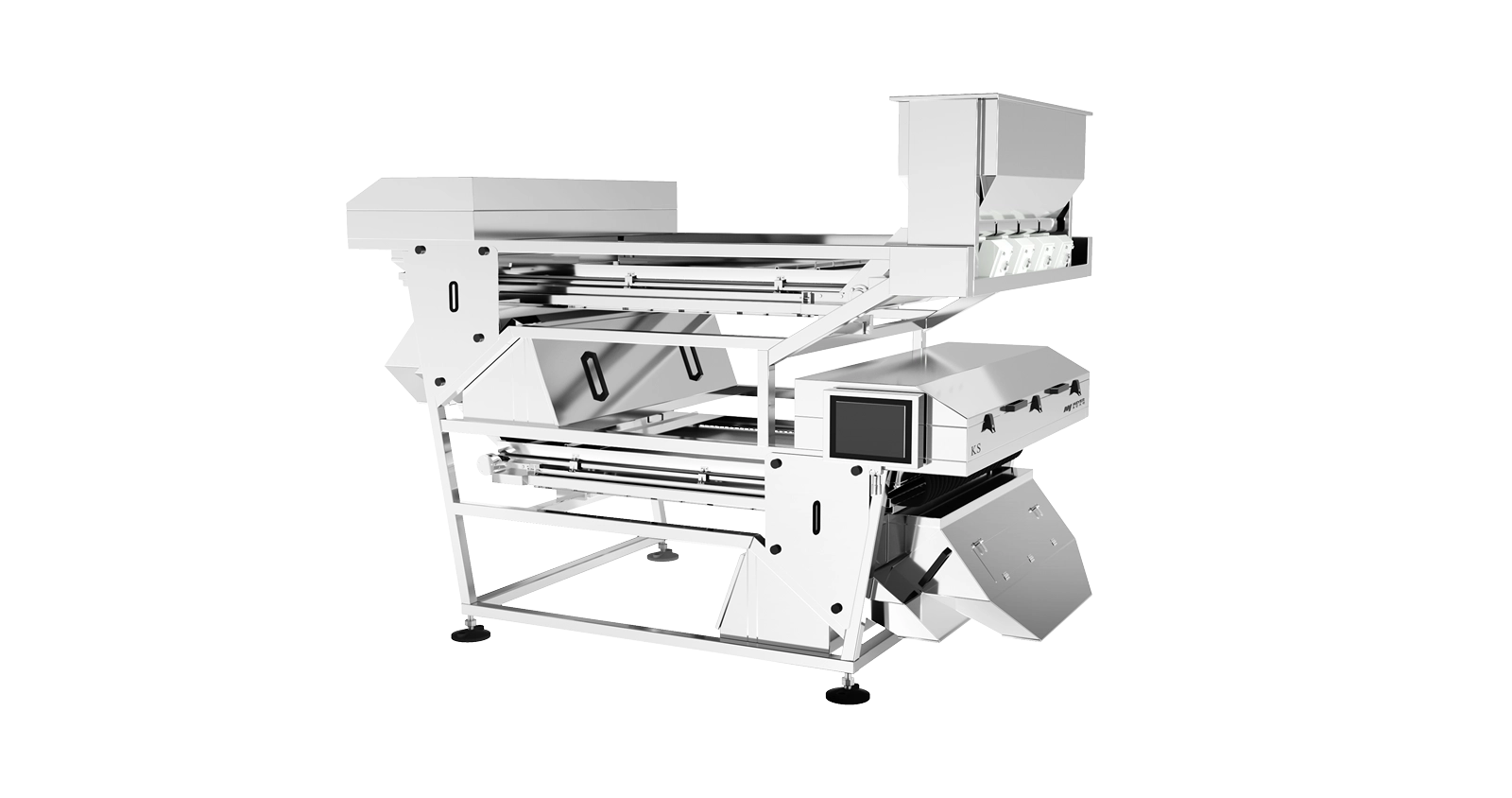

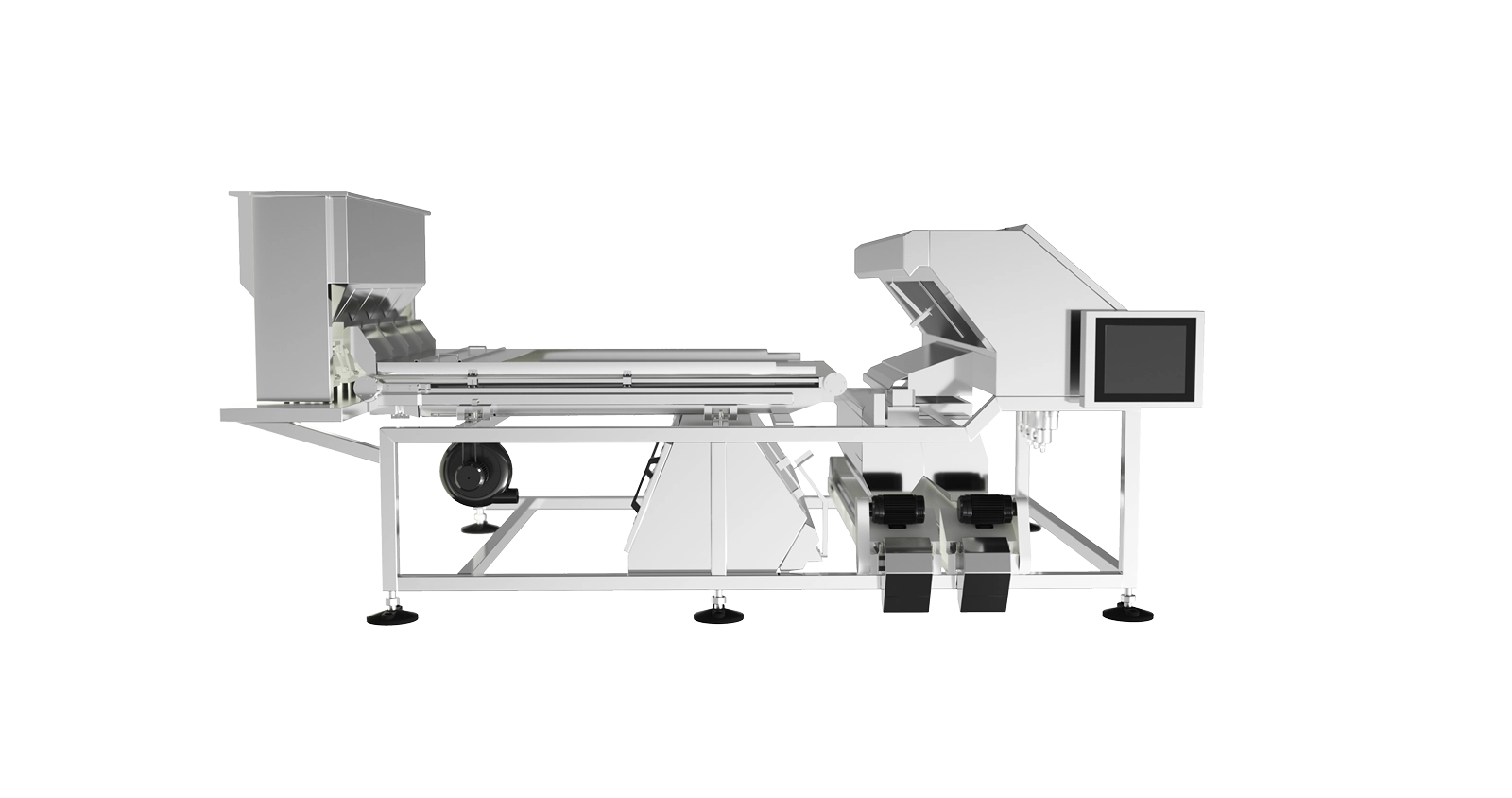

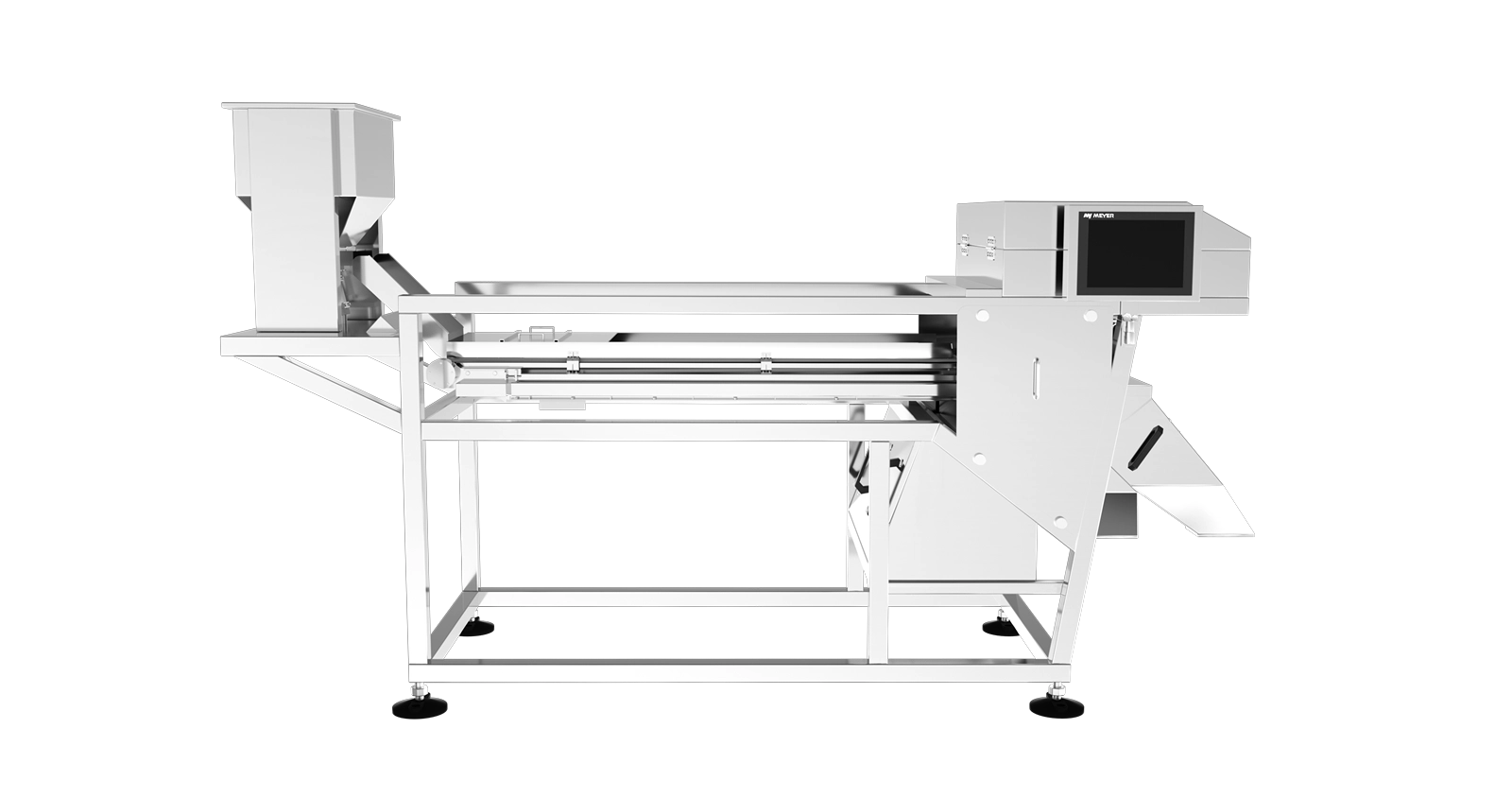

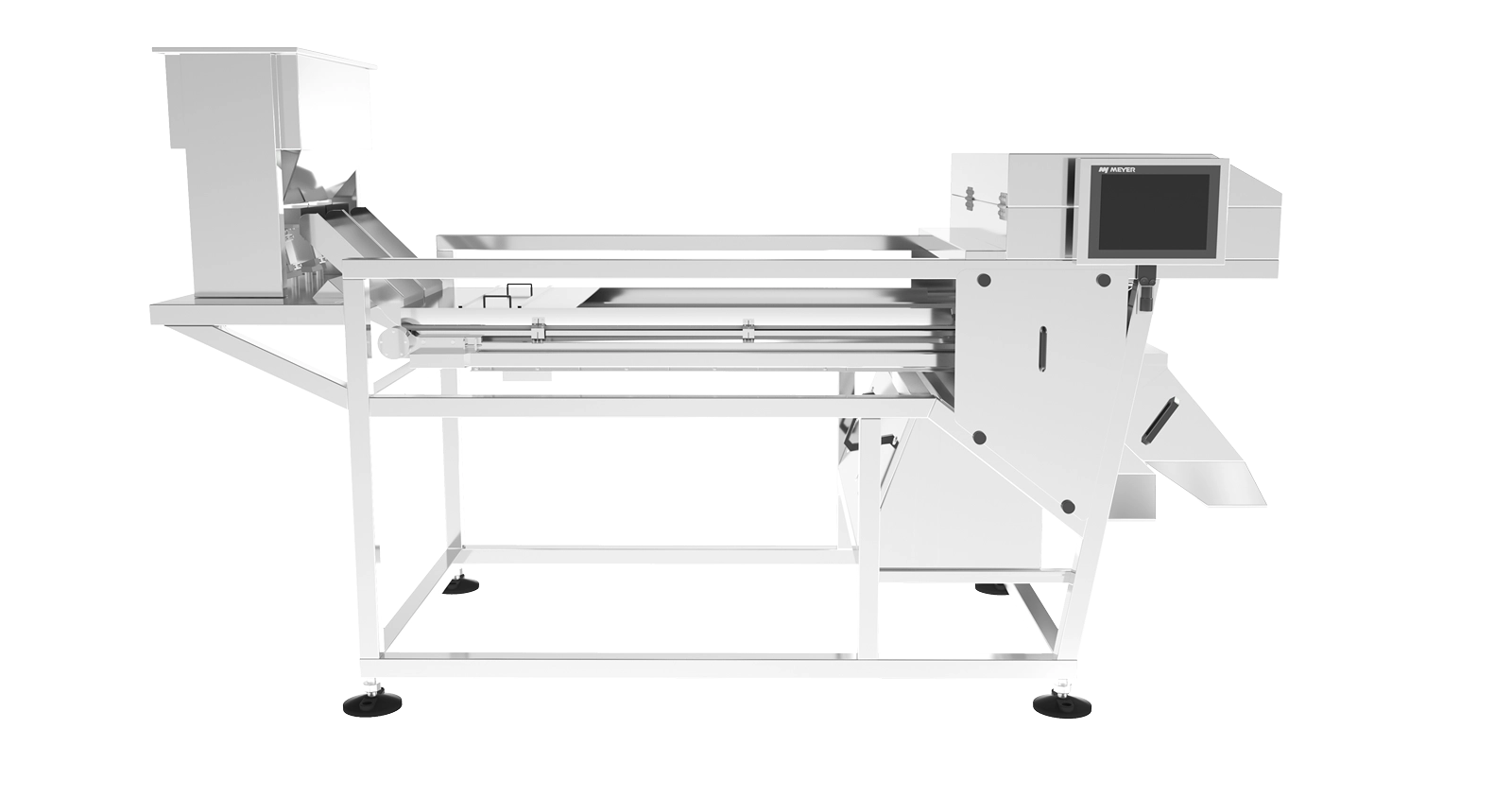

See all chute color sortersBelt color sorters

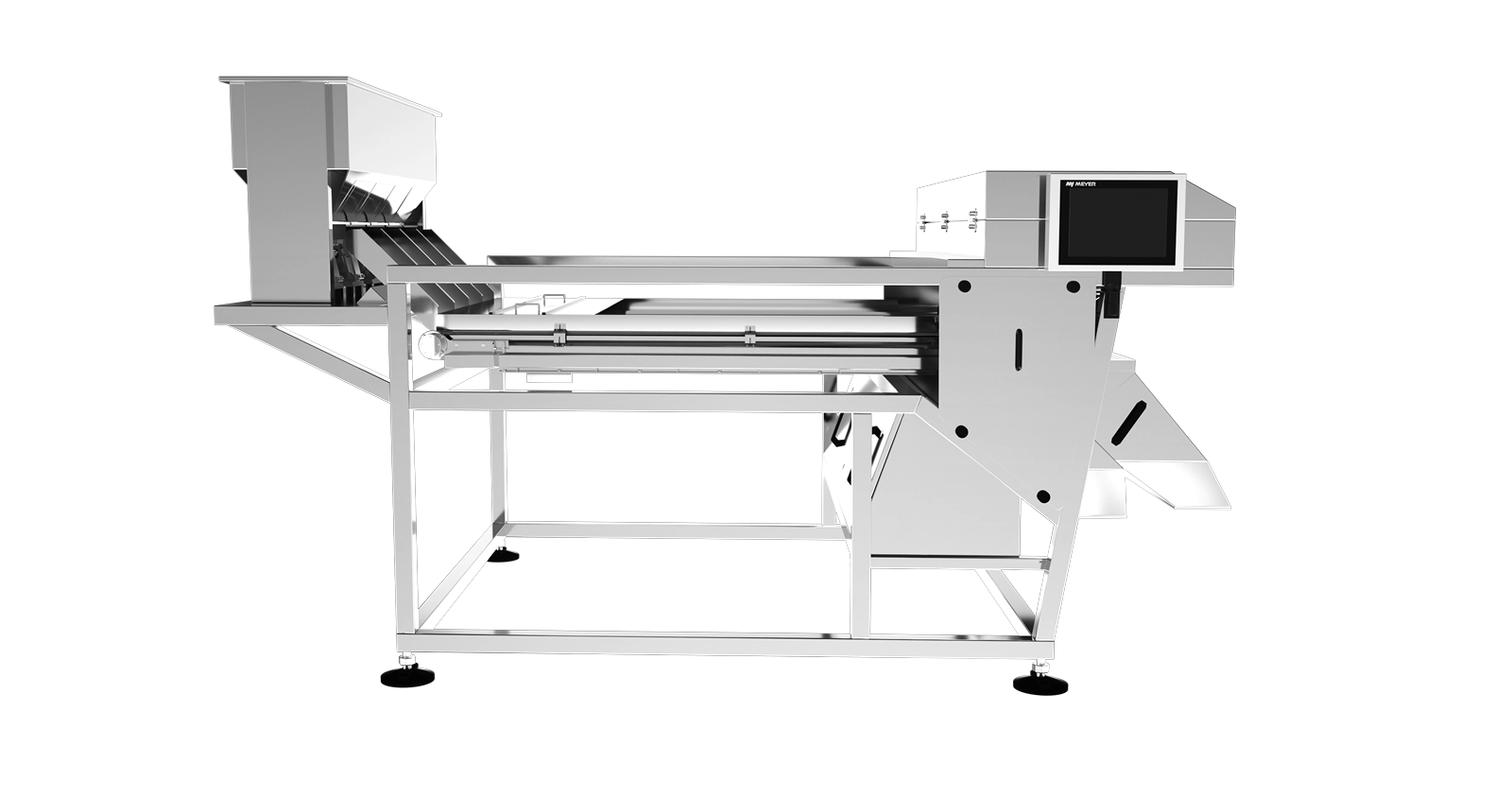

Belt color sorters are a solution designed for sorting sensitive materials, such as seeds, nuts, and tea leaves. With the technology used, these devices allow for effective separation of fractions based on slight differences in color and shape, enabling the elimination of undesirable elements, including damaged or discolored products, as well as foreign bodies. Thanks to the belt transport system, our machines ensure that delicate products are handled with the utmost care, minimizing the risk of damage. These sorters excel in the food, agriculture, and recycling industries, where precise separation is crucial for maintaining the high quality of the final product. Available configuration options allow for customization of the equipment to meet specific production requirements.

See all belt color sortersObject sorters

Our object sorters (for bottle sorting) are precision devices designed for the separation of large objects at the beginning of the production line. Using Deep Learning AI technology, they recognize shape and color, allowing for the effective sorting of PET bottles, HDPE bottles, cans, and Tetra Pak containers. Depending on the configuration, they can be equipped with InGaAs cameras that enable the identification of material types, such as different polymers. This reliable solution is ideal for recycling and processing industries, supporting process automation and increasing production efficiency. Intelligent algorithms minimize raw material waste and ensure high purity of recovered fractions. With MEYER sorters, recycling becomes more efficient and sustainable.

See all object sortersChute polymer sorters

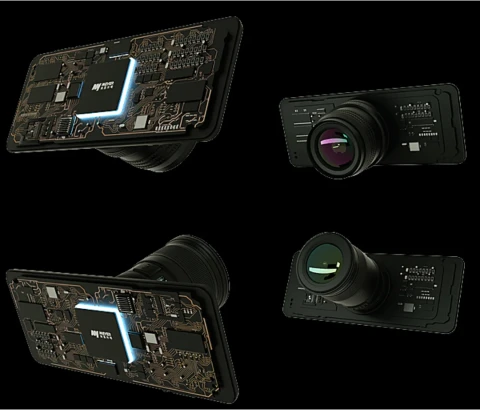

MEYER polymer sorters are designed to optimize material recovery processes in recycling. With precise sorting technology, our machines effectively separate materials into different polymer fractions, ensuring high-quality processed material. Equipped with an Ultra-HD camera system and an industrial-grade CCD sensor, MEYER sorters achieve exceptional recognition accuracy, enabling the identification of even the smallest details in the material. The modular design of the machine guarantees reliability and long-term stability, while the digital electrical control system ensures trouble-free operation. Additionally, our devices feature color sorting functionality, further enhancing the precision of material segregation.

See all chute polymer sortersColor Sorters with InGaAs

MEYER color sorters with InGaAs cameras are designed for maximum precision in the selection of food and agricultural products. By utilizing infrared technology, these machines can identify not only differences in color but also variations in material density, allowing for the effective detection of defective grains, moldy seeds, or contaminants such as ergot. Advanced sorting algorithms enable the distinction between different grain and seed varieties, ensuring a higher quality final product. Additionally, the system efficiently removes foreign objects like stones, twigs, and other impurities that could negatively impact further.

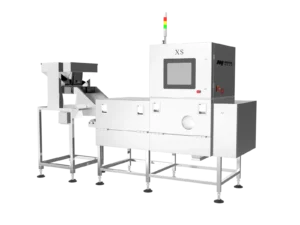

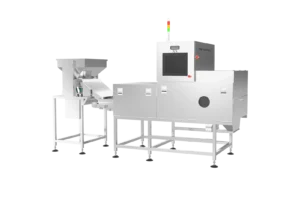

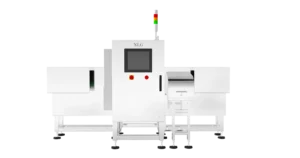

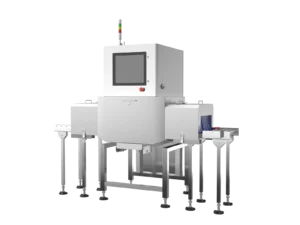

See all color sorters with InGaAsX-Ray detectors

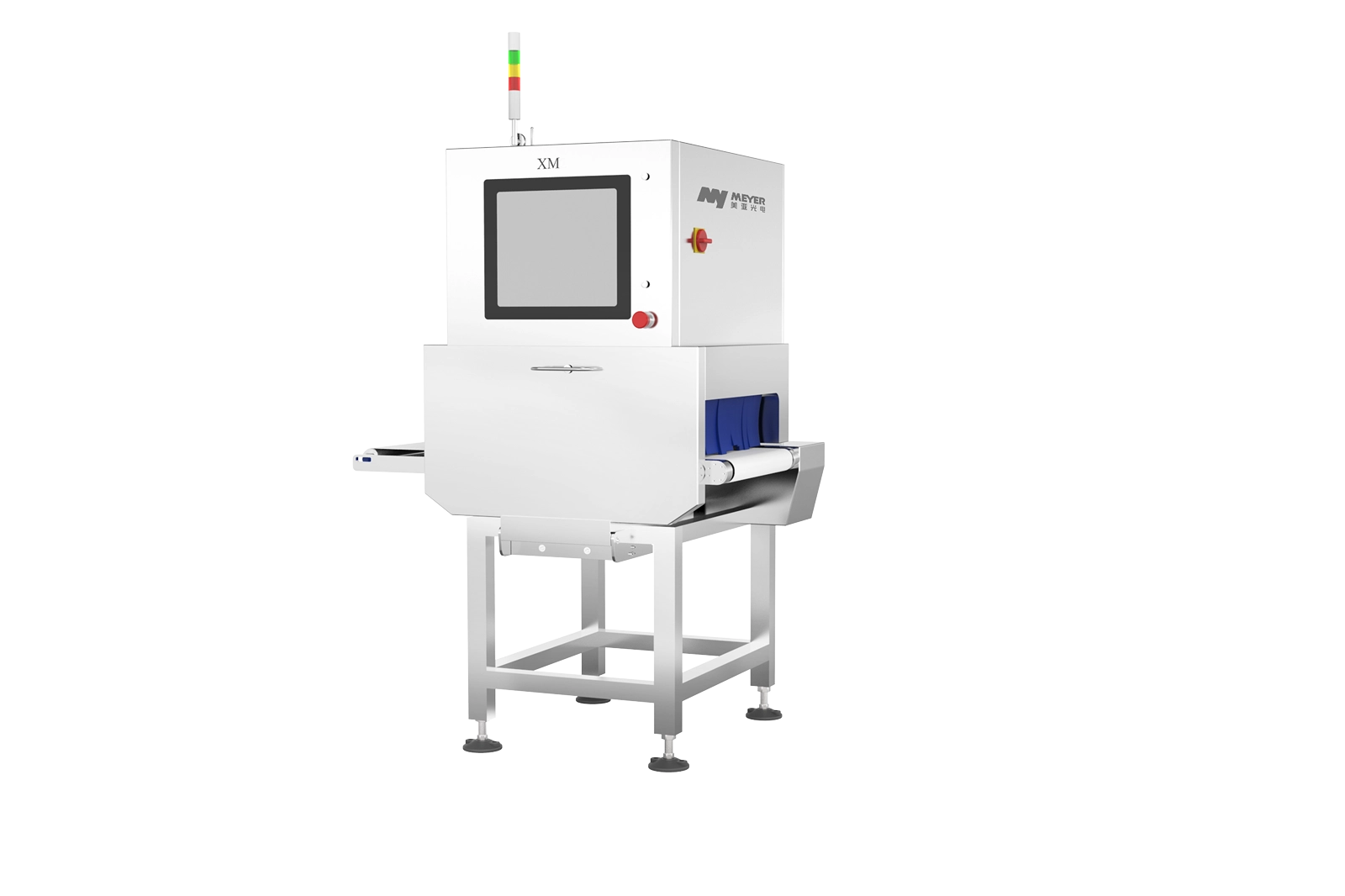

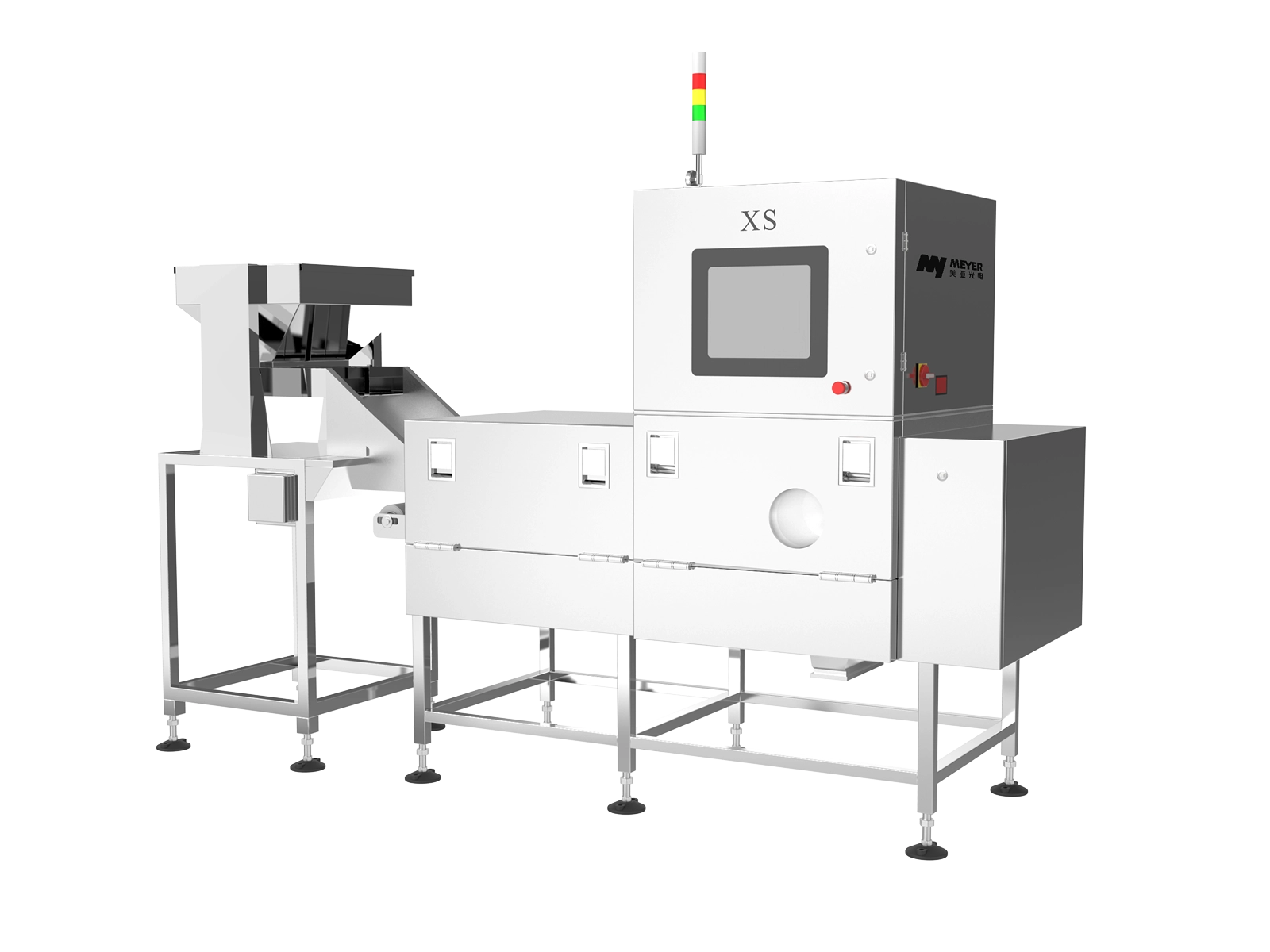

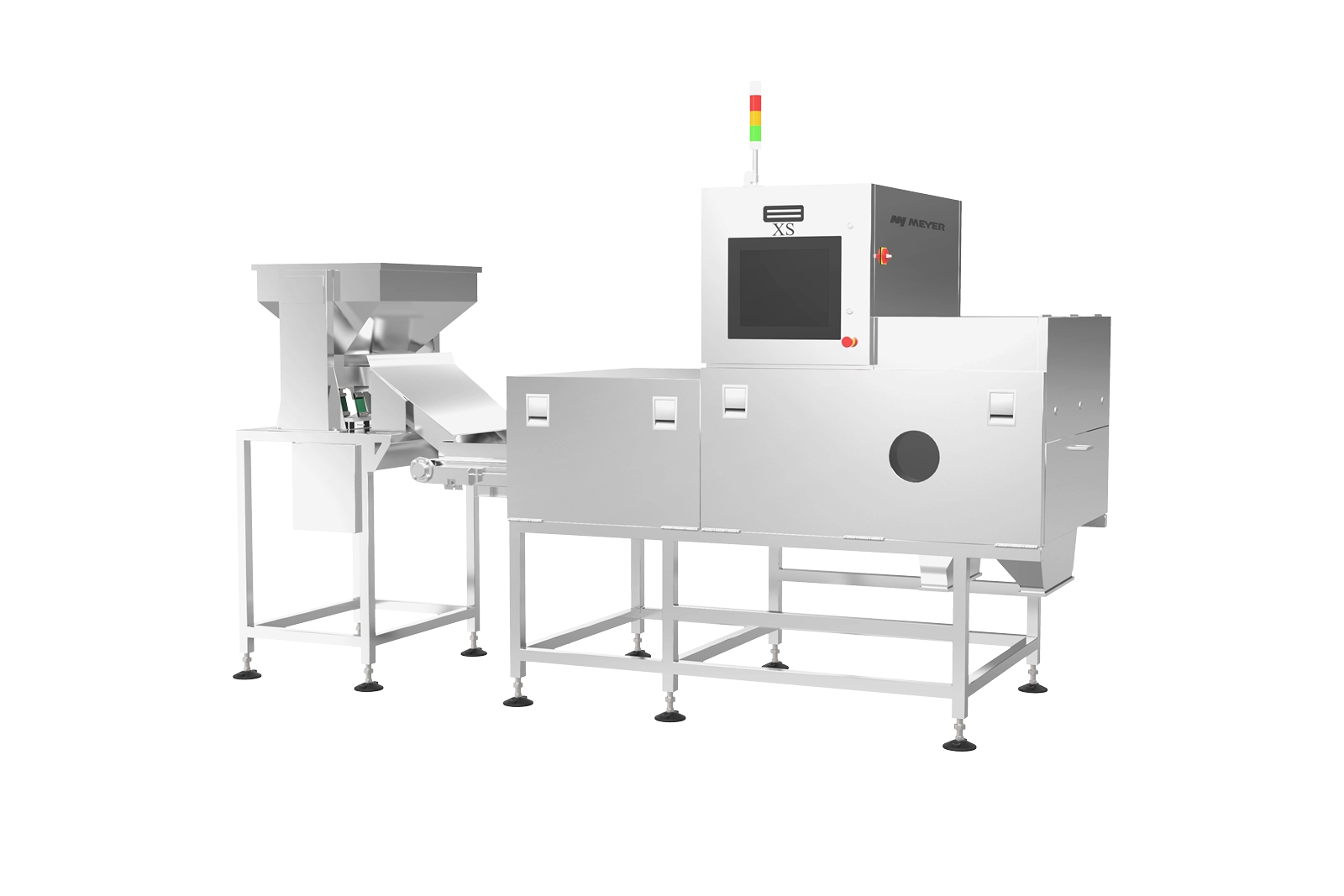

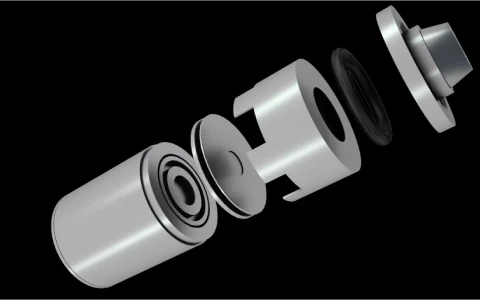

MEYER X-ray detectors utilize X-ray technology for precise detection and removal of contaminants. With advanced high-resolution sensors and patented image analysis algorithms, the system can identify even the smallest unwanted elements, including foreign objects with a density similar to the product itself. The Sniper System, equipped with magnetic ejectors, ensures precise and gentle impurity removal while minimizing raw material loss. Intelligent features such as AI-driven systems, automatic optimization, and remote monitoring enhance the sorting process and improve efficiency. These innovations make MEYER a guarantee of the highest level of safety and quality in food and industrial product inspection.

See all X-Ray detectorsAdvantages of our products

Our clients’ stories

Frequently Asked Questions

What does the process of selecting optical sorting solutions look like?

The process of selecting optical sorting solutions begins by contacting our representative. Based on the type of material and the provided information, our sales team will guide you on how to prepare and send the material to our test center. The MEYER service team will then develop sorting solutions for your needs, and you’ll be invited to witness the testing process firsthand, allowing you to see the results on your own sample and discuss customized solutions with our sales representative.

What industries can benefit from optical sorting solutions?

Optical sorting solutions are highly versatile and can benefit a wide range of industries. These include:

- Food Industry: Ensuring the quality and safety of products like fruits, vegetables, grains, nuts, and beverages by removing foreign materials and defective items.

- Recycling and Waste Management: Sorting recyclable materials such as plastics, metals, glass, and paper for efficient processing.

- Agriculture: Sorting seeds, crops, and other agricultural products to meet quality standards.

Optical sorters enhance efficiency, reduce waste, and maintain high product quality, making them essential in industries where precision and quality control are critical.

What types of materials can be sorted at the Meyer Europe machines?

You can view the list of materials that Meyer sorters can handle under the Solutions > Materials tab. If you don’t see your material listed, please contact us to discuss your needs with our sales representative.

List of materials:

- Plastic

- PET

- PP

- HDPE

- PVC

- Metal

- Rubber

- Glass

- Rice

- Nuts

- Meat & seafood

- Canned & bottled food

- Fruits & vegetables

- Packed food

- Seeds & grains

- Beans & pulses

- Coffee

- Tea