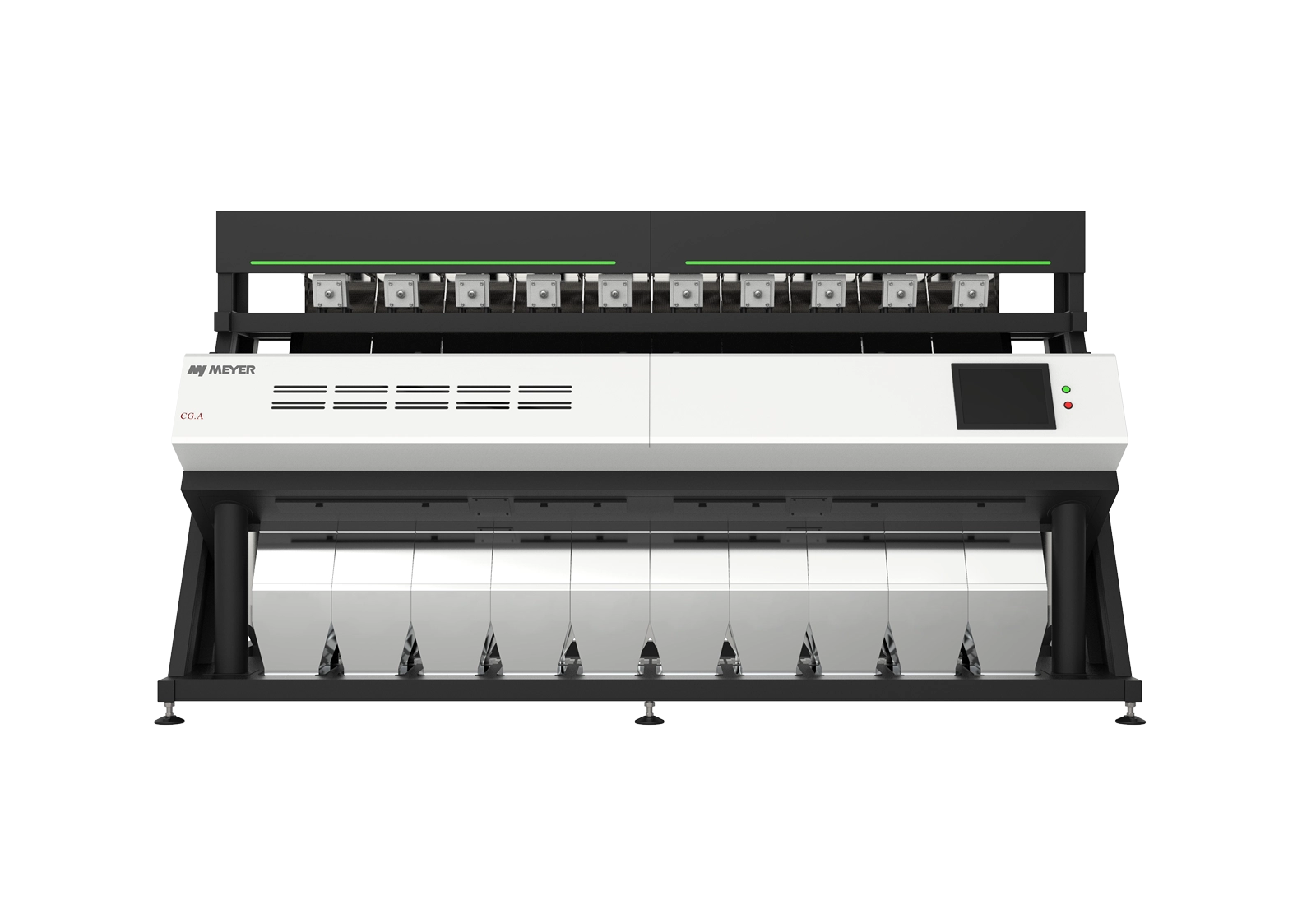

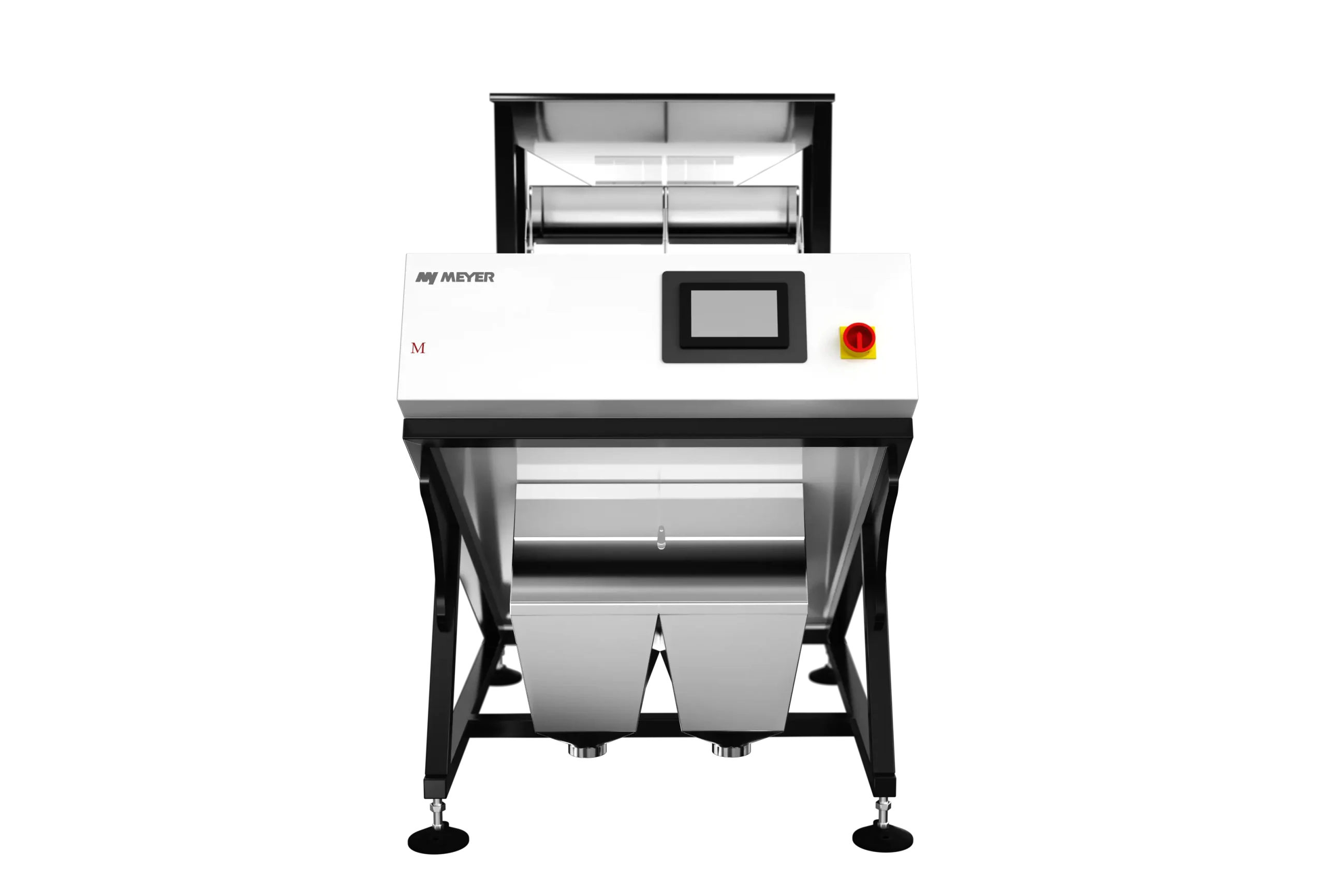

Sorter details

Meyer Technology

Send inquiryTest center

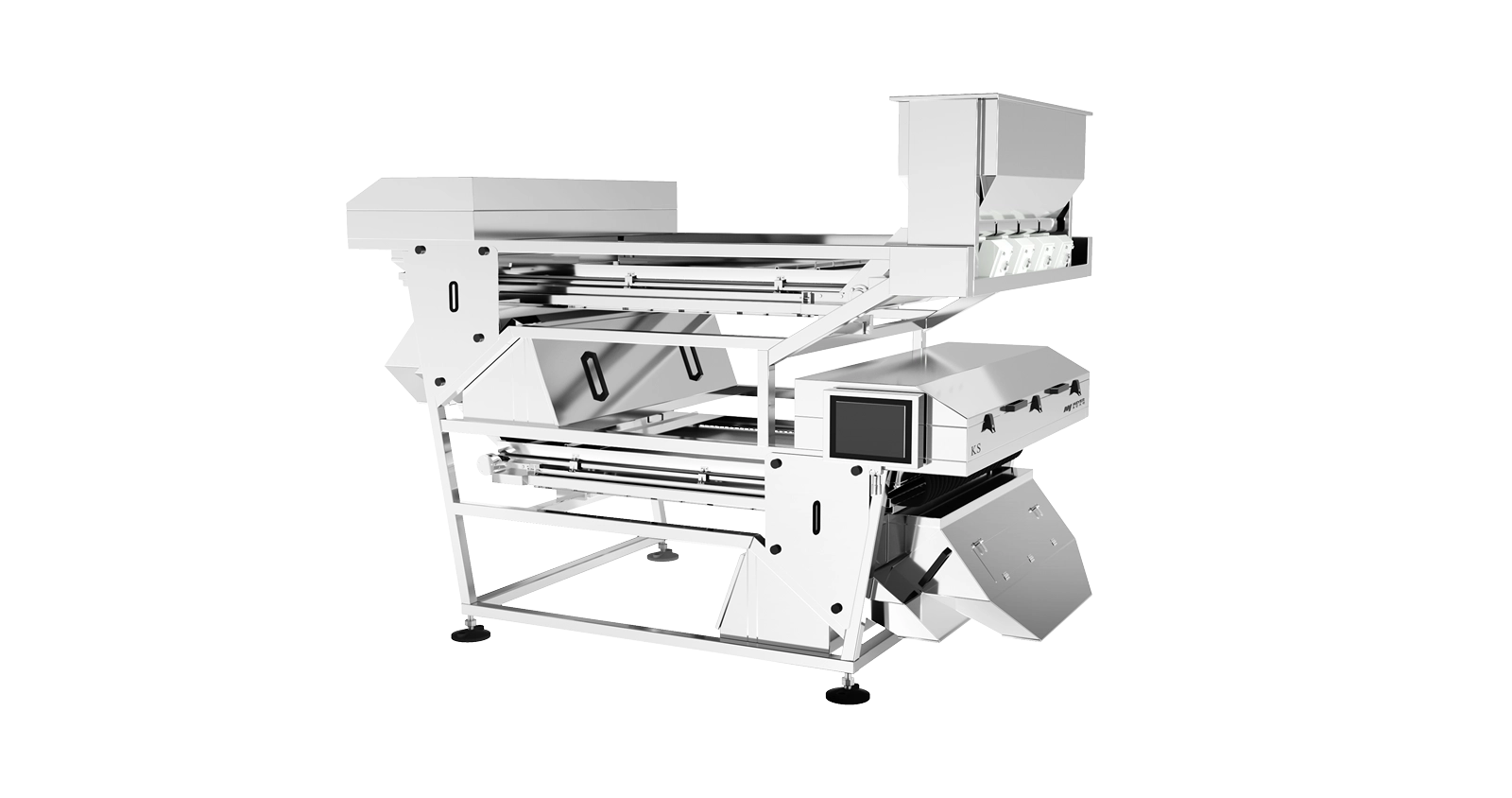

Specifications

Model:

CG10 600CG.SChutes:

10Throughput:

up to 2 t / hSorting accuracy:

99.99 %Power:

4.0 kWPower Voltage:

AC 180~240 V V / 50HzAir source pressure:

0.6 - 0.8 MPaWeight:

2090 kgDimensions:

3583 x 2020 x 1564 mmOptical sorting use cases

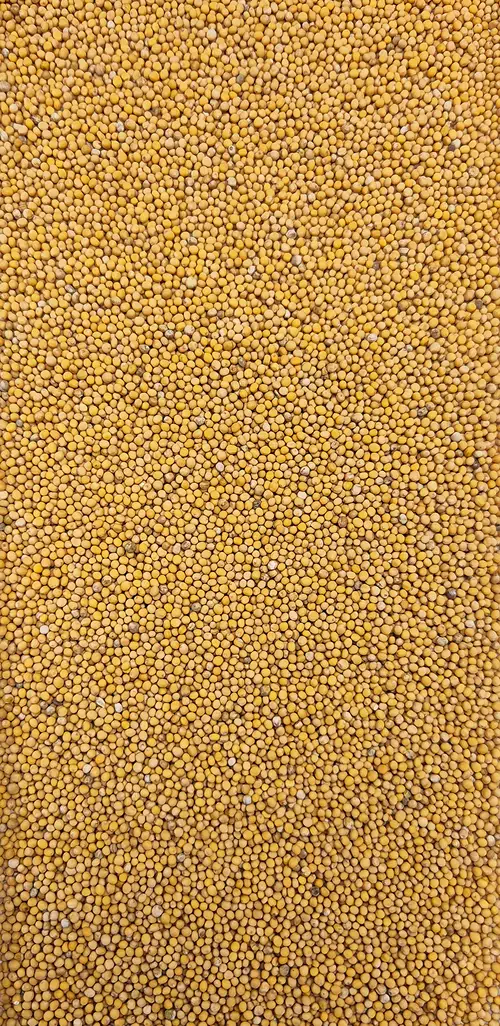

Material sorting samples and applications

INPUT

ACCEPT

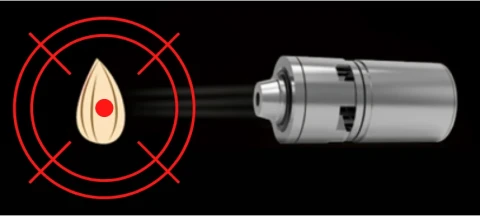

REJECT

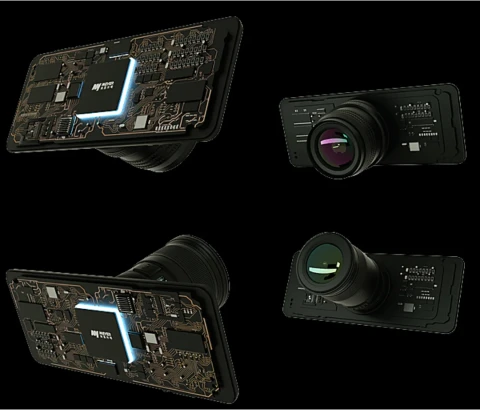

Product features

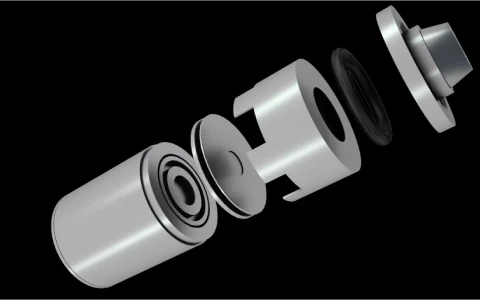

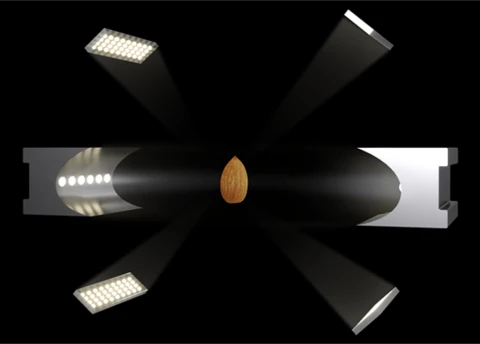

Our solutions are based on modern technology

Our services

We will help you on every step

Pre-Sale Service

- Consultation on selecting the optimal optical sorter tailored to your needs.

- Support in integrating the machine with existing production lines.

- Assistance in designing new lines with the sorter as a key component of the installation.

- Material testing at our center – with the opportunity to attend and observe the process live.

- Comprehensive technical consultations to ensure optimal implementation and maximum efficiency

After Sale Service

- On-site service with quick response times and full commitment.

- Warranty including free inspections and maintenance.

- Consulting support for device usage and optimization.

- Individual service documentation ensuring a complete service history.

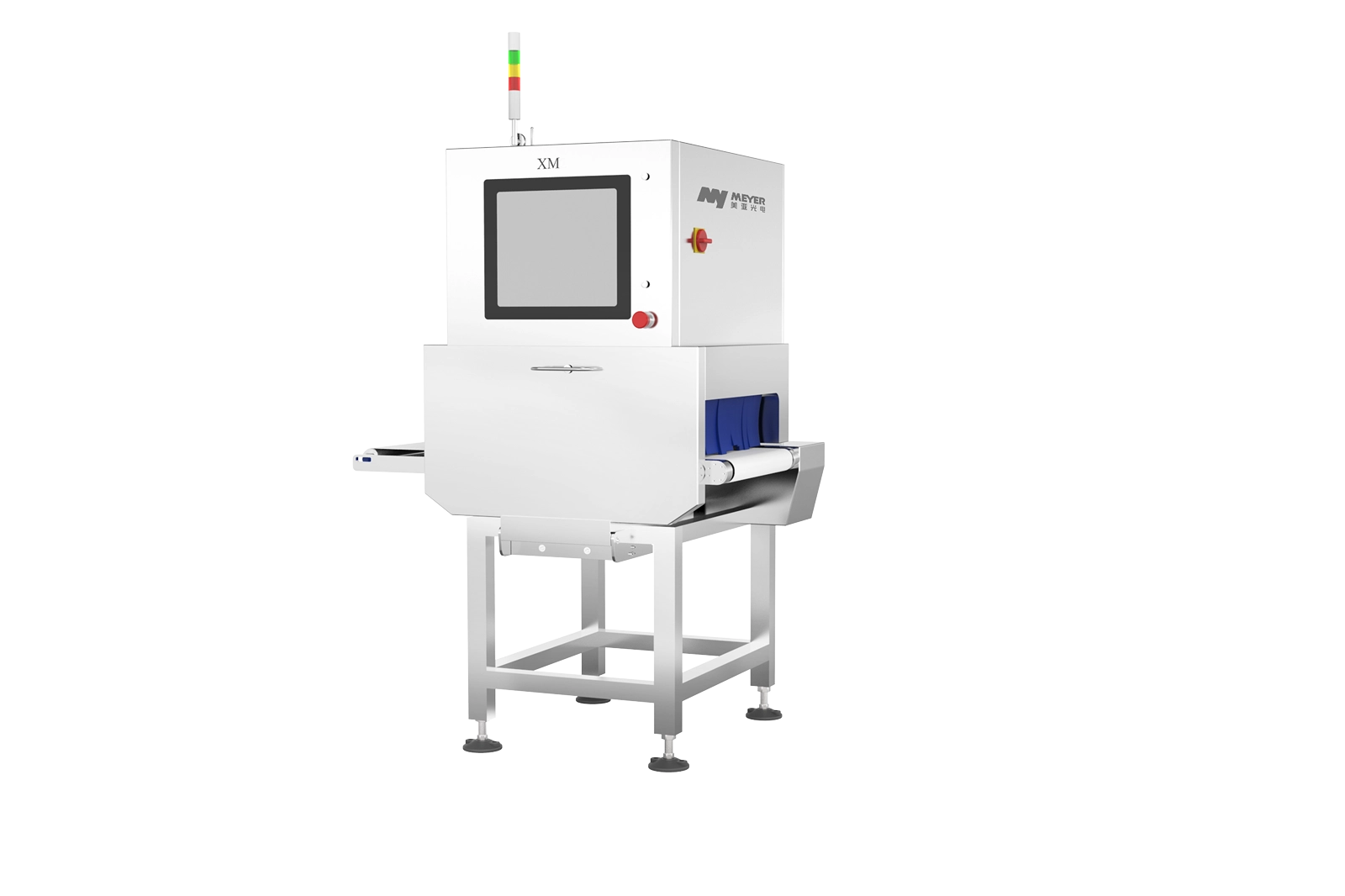

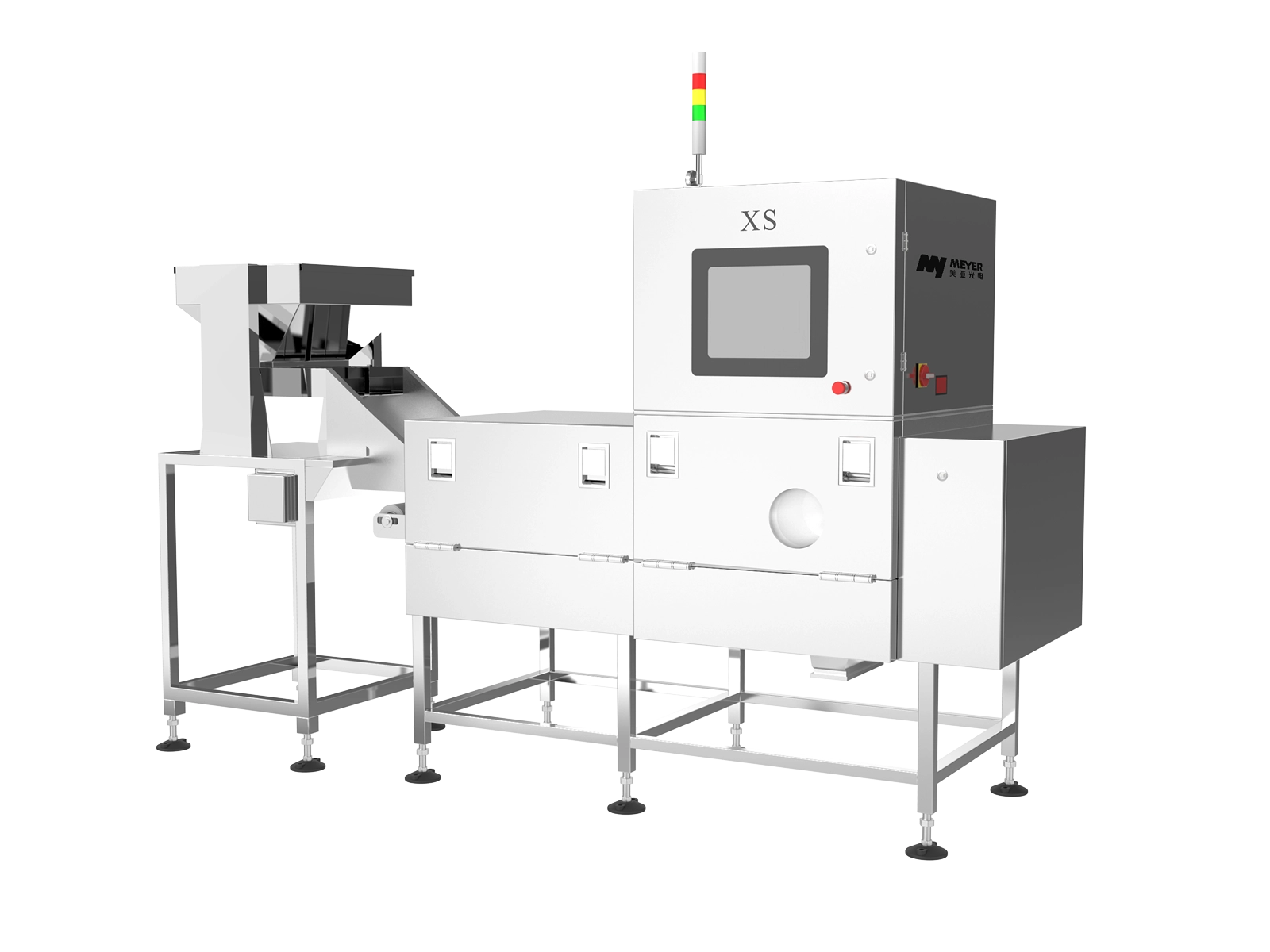

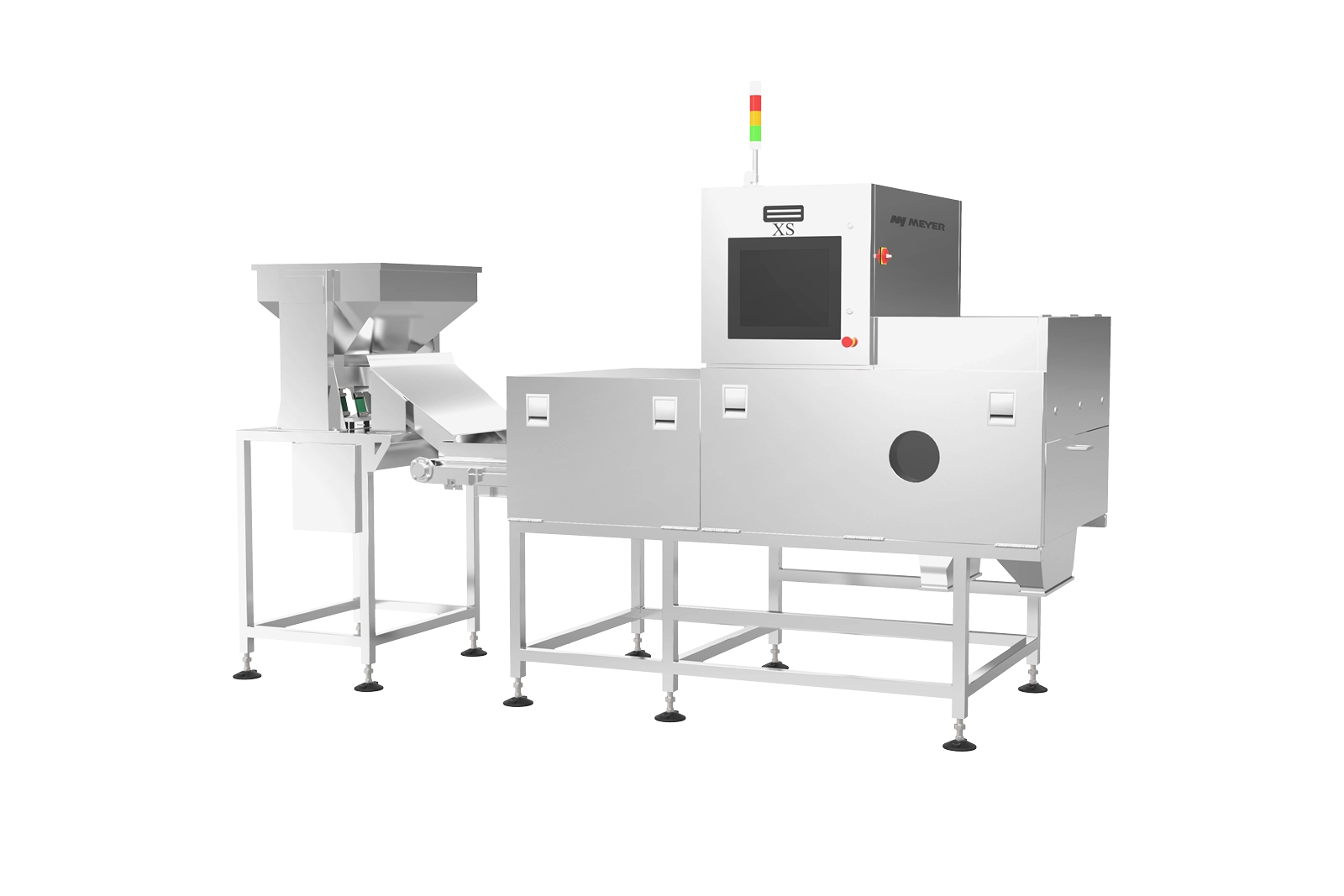

Related products

Optical sorting solutions

FAQ

Frequently Asked Questions

Do I have any guarantee on Meyer products?

The 5-year guarantee covers all material and production defects in Meyer products.

Is the support available in all EU countries?

Content goes here ..

Contact Us