Seeds & grains sorting

Enhancing Seeds & grains sorting efficiency with Meyer advanced sorting technology

Improve Seeds & grains sorting quality and increase throughput

Seeds & grains optical sorting process

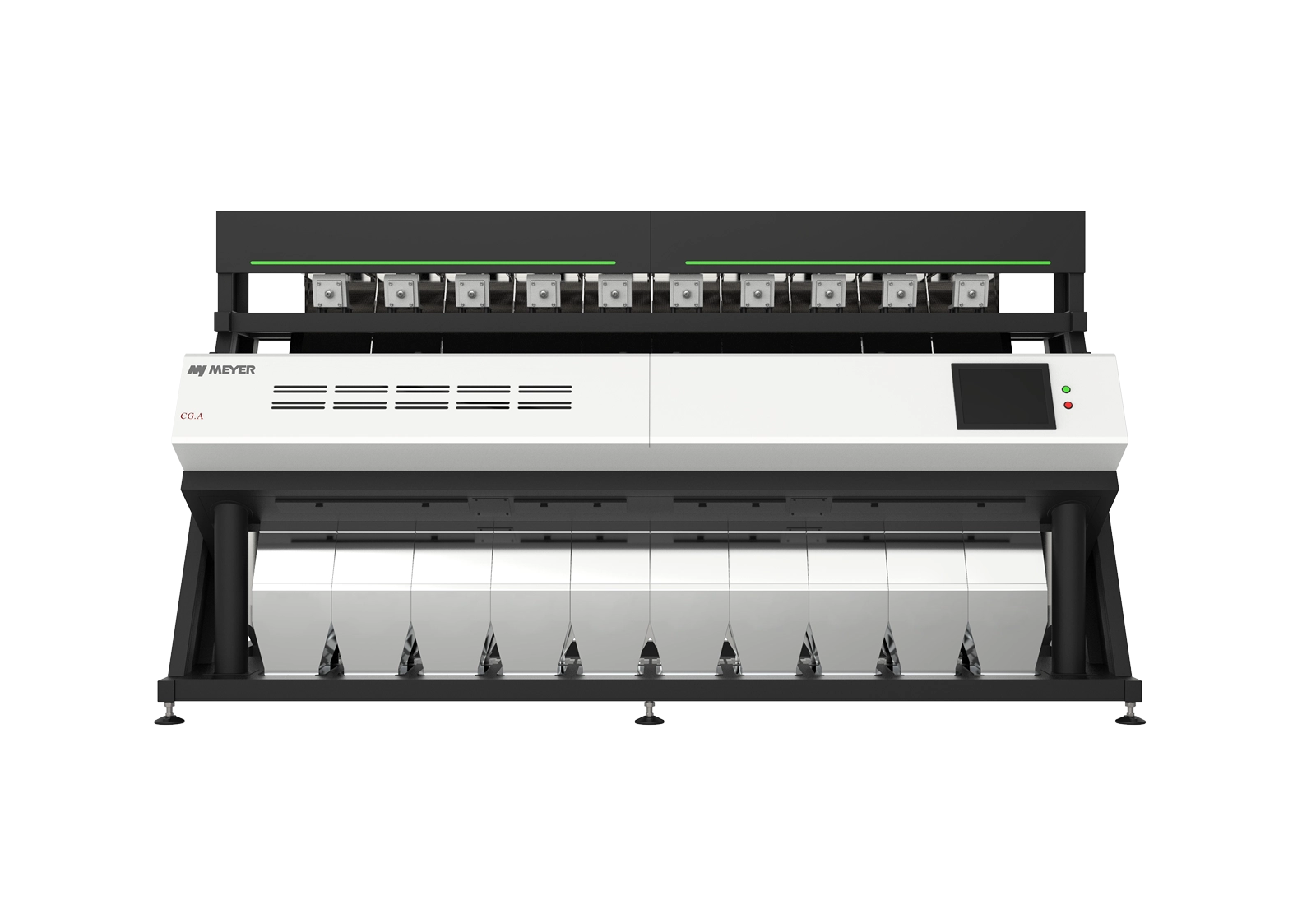

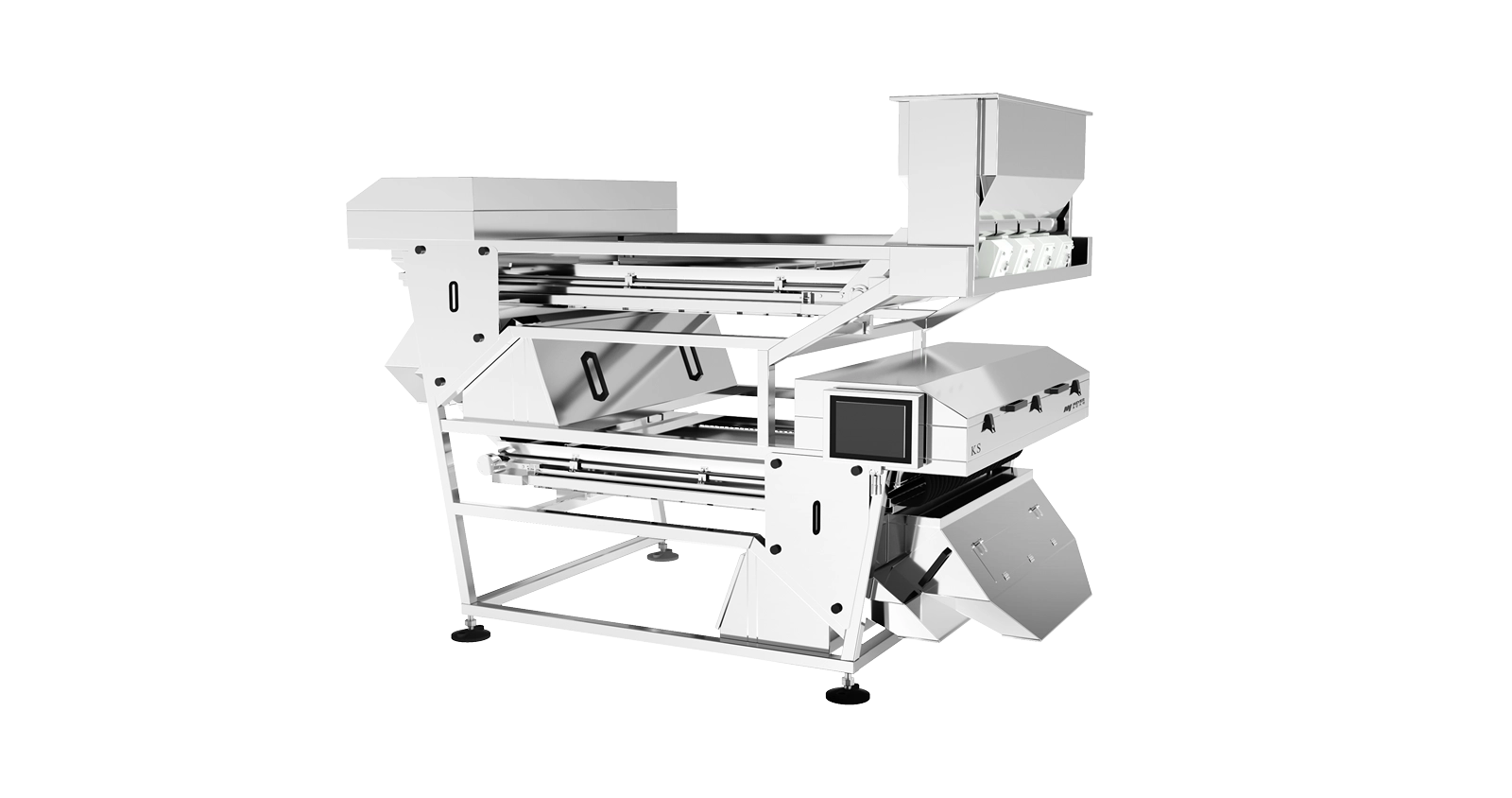

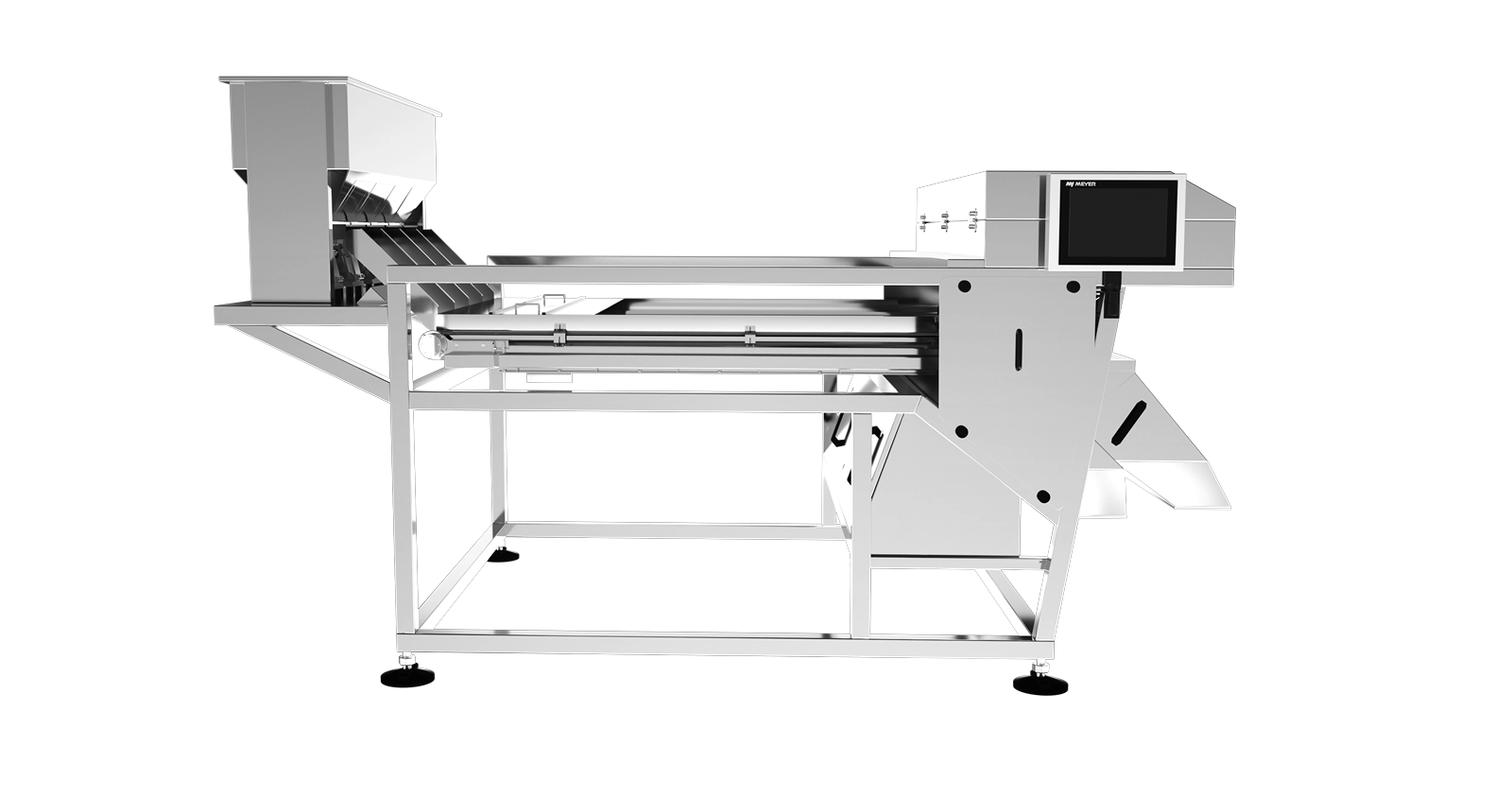

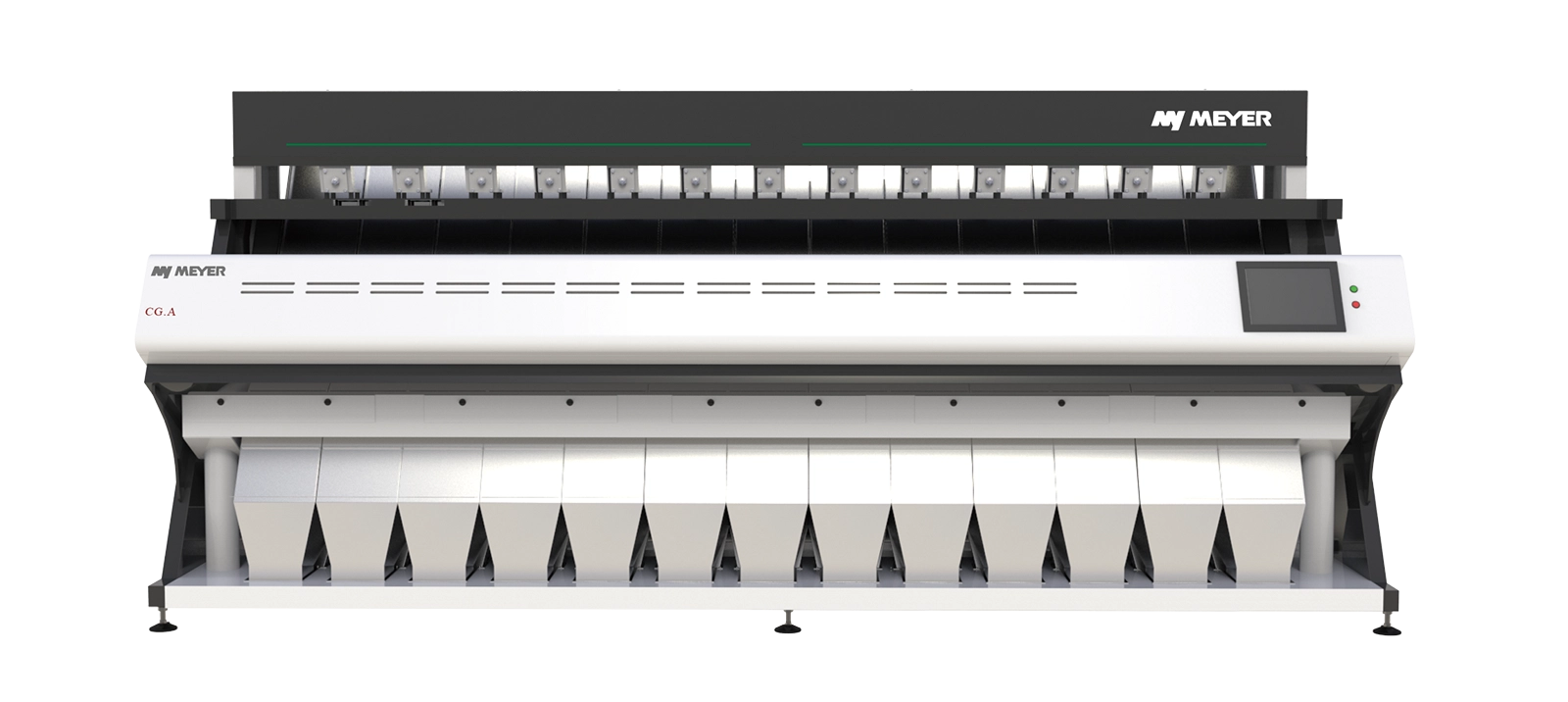

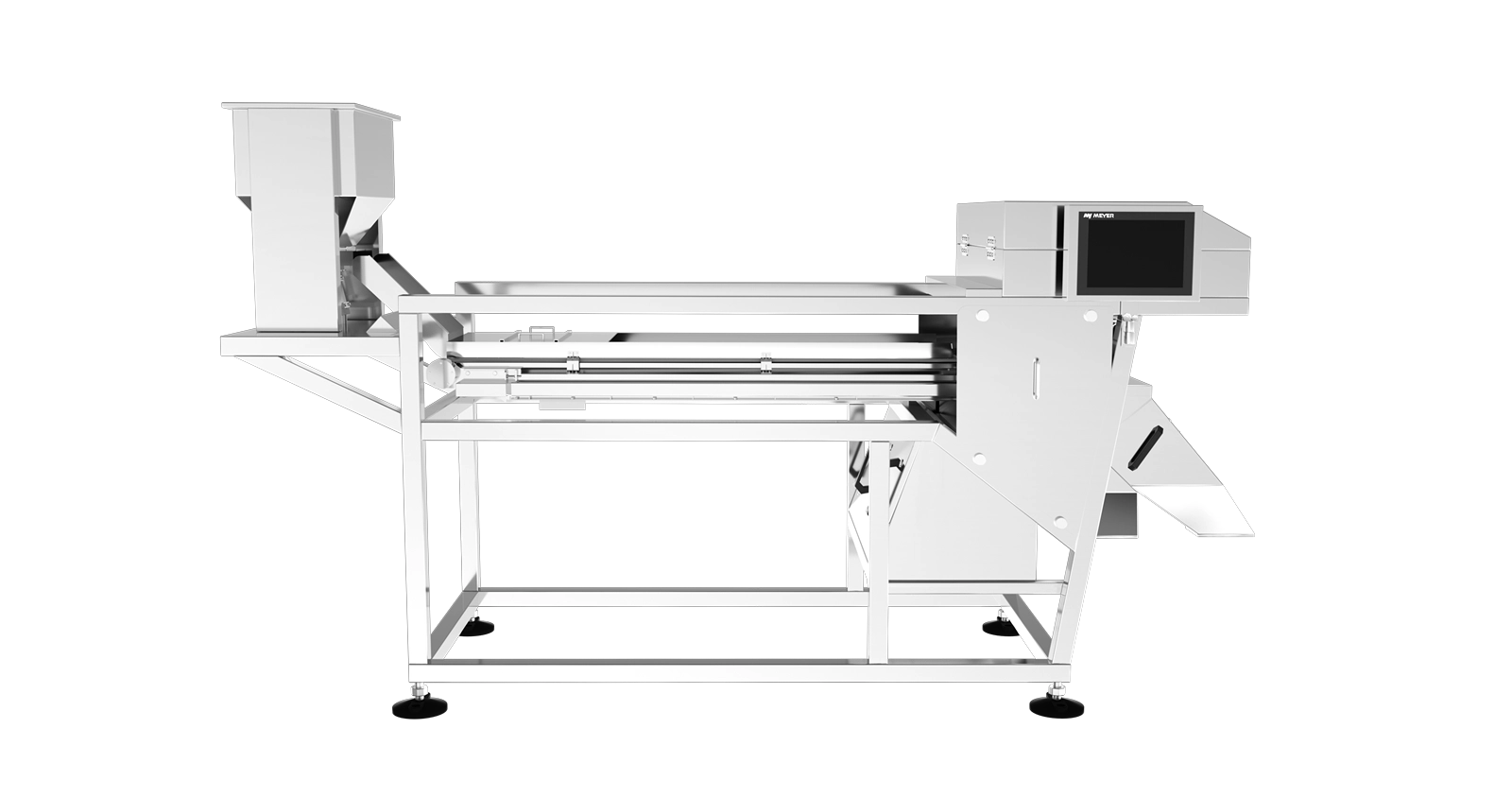

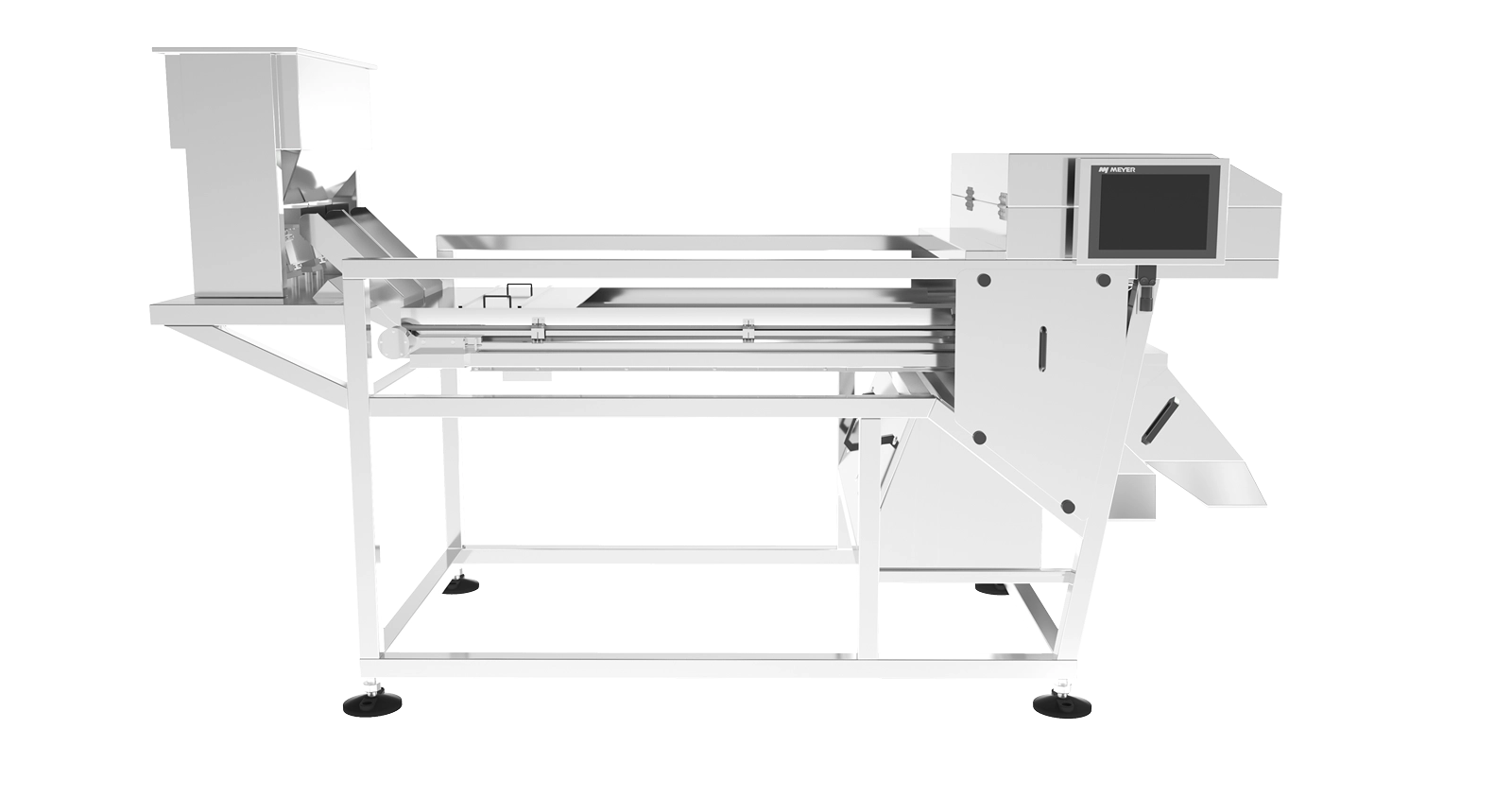

Meyer offers a wide range of solutions for sorting seeds and grains, including wheat, corn, rye, barley, oat, buckwheat, millet, and many others. Our advanced sorting systems are tailored to meet individual customer needs, ensuring maximum efficiency and precision. The product range includes color sorters, sorters equipped with UV and InGaAs cameras, as well as X-ray detectors, enabling comprehensive quality control. By utilizing the latest technologies, our devices effectively detect and remove foreign objects, discolored, damaged grains, and those contaminated with aflatoxins. The wide selection of available solutions allows for precise cleaning and selection of materials.

See sorting samples

Examples of Seeds & grains sorting with Meyer

Best sorting machines for Seeds & grains sorting

Benefits of using Seeds & grains sorting machines

Increased purity and quality

Optical sorters can detect and remove discolored materials, foreign materials, and defects such as stones, sticks, or damaged grains. This results in higher purity and quality of the final Seeds & grains product, meeting consumer and market standards.

Better Efficiency and Throughput

Optical sorting technology allows for the processing of large volumes of Seeds & grains quickly and accurately, significantly improving throughput compared to manual sorting methods.

Reduced Labor Costs

Automated sorting reduces the need for manual labor, leading to cost savings and reduced human error in the sorting process.

Improved Product Value

Higher quality and purity of sorted Seeds & grains can lead to better market prices and customer satisfaction.

Versatility and Flexibility

Optical sorters can be used for different varieties of Seeds & grains and can be adjusted for different sorting needs, making them versatile tools in Seeds & grains processing.

Reduced Waste

Efficient sorting helps reduce waste by ensuring that only genuinely defective materials are removed, while maximizing the amount of good product.

Data Collection and Analysis

Modern optical sorting systems can collect valuable data about the waste stream, such as composition and contamination levels, aiding in process optimization and regulatory compliance.

Decreased Environmental Impact

By increasing the amount and quality of recycled materials, optical sorters contribute to reduced reliance on virgin resources, lower greenhouse gas emissions, and a smaller environmental footprint for waste management operations.

Enhanced Product Safety

By removing contaminated grains or foreign objects, optical sorters help prevent potential health hazards, contributing to safer products.

Our clients’ stories

Frequently Asked Questions

What are the advantages of using UV and InGaAs cameras in the sorting process?

UV cameras effectively identify mold, fungi, and other contaminants that are invisible to visible light, helping to detect and reject seeds contaminated with aflatoxins, for example. On the other hand, the use of InGaAs cameras in the sorting process of grains and seeds allows for the identification and elimination of grains with altered internal structures—soft or moldy seeds inside.

How does sorting with InGaAs cameras differ from traditional optical sorting?

Sorting with InGaAs cameras differs from traditional optical sorting primarily in the range of light spectrum analyzed. Standard optical systems use RGB cameras that assess the appearance of seed surfaces in the visible light spectrum, allowing for the detection of discoloration, damage, or shape differences. In contrast, InGaAs technology operates in the near-infrared (NIR) range, enabling the identification of differences in seed density, not just color.

Can Meyer sorters detect seeds contaminated with aflatoxins?

Yes, Meyer sorters can detect seeds contaminated with aflatoxins. They use UV cameras to identify fluorescence changes in seeds, which may indicate the presence of mold and fungi producing aflatoxins.