Meyer Technology

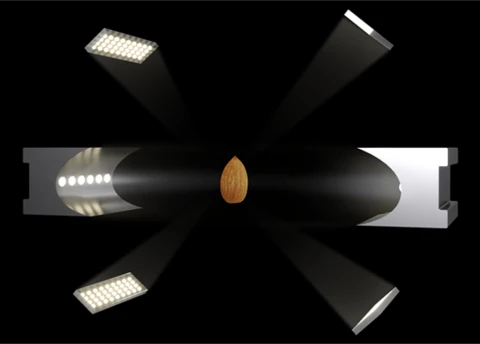

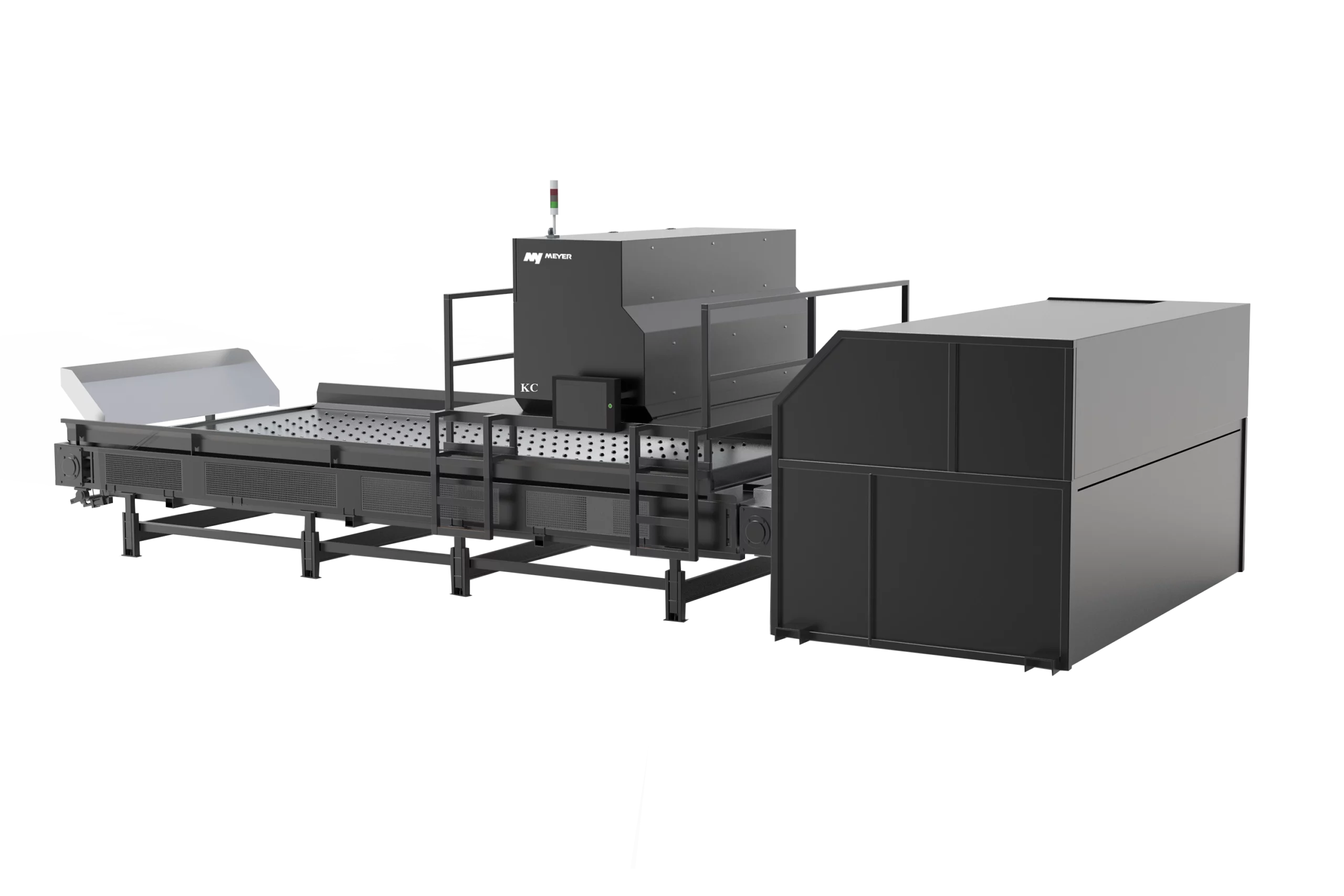

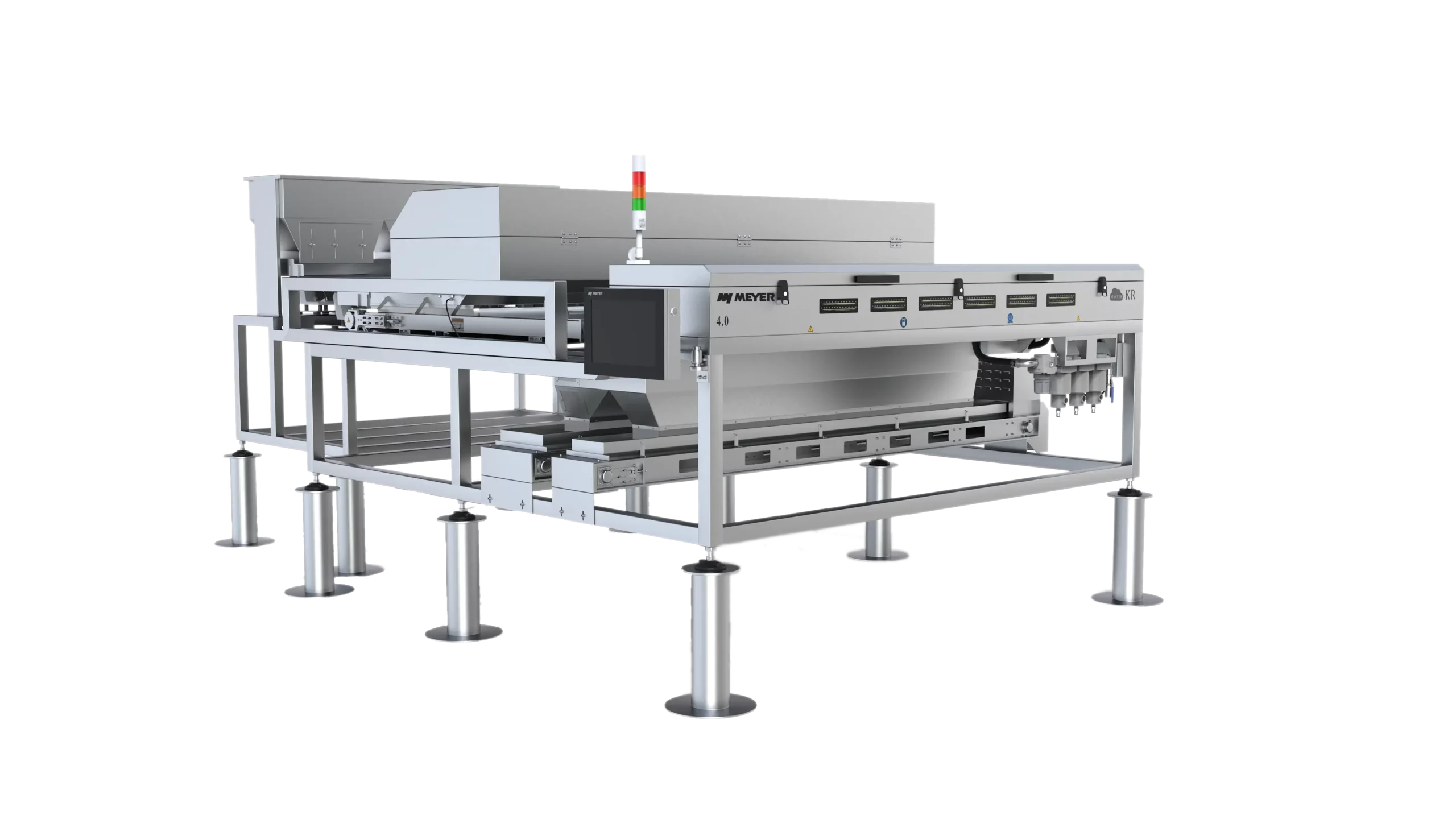

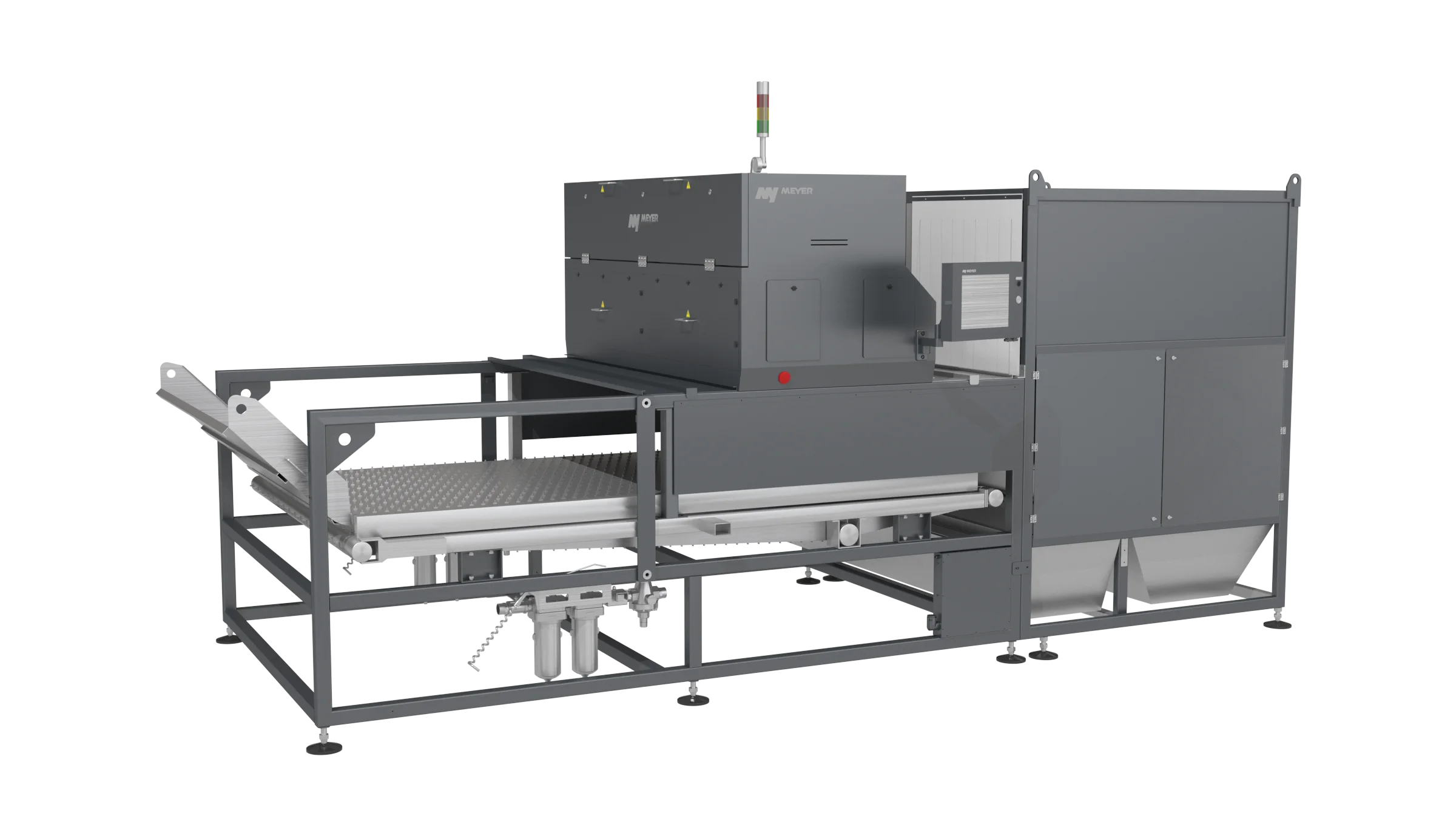

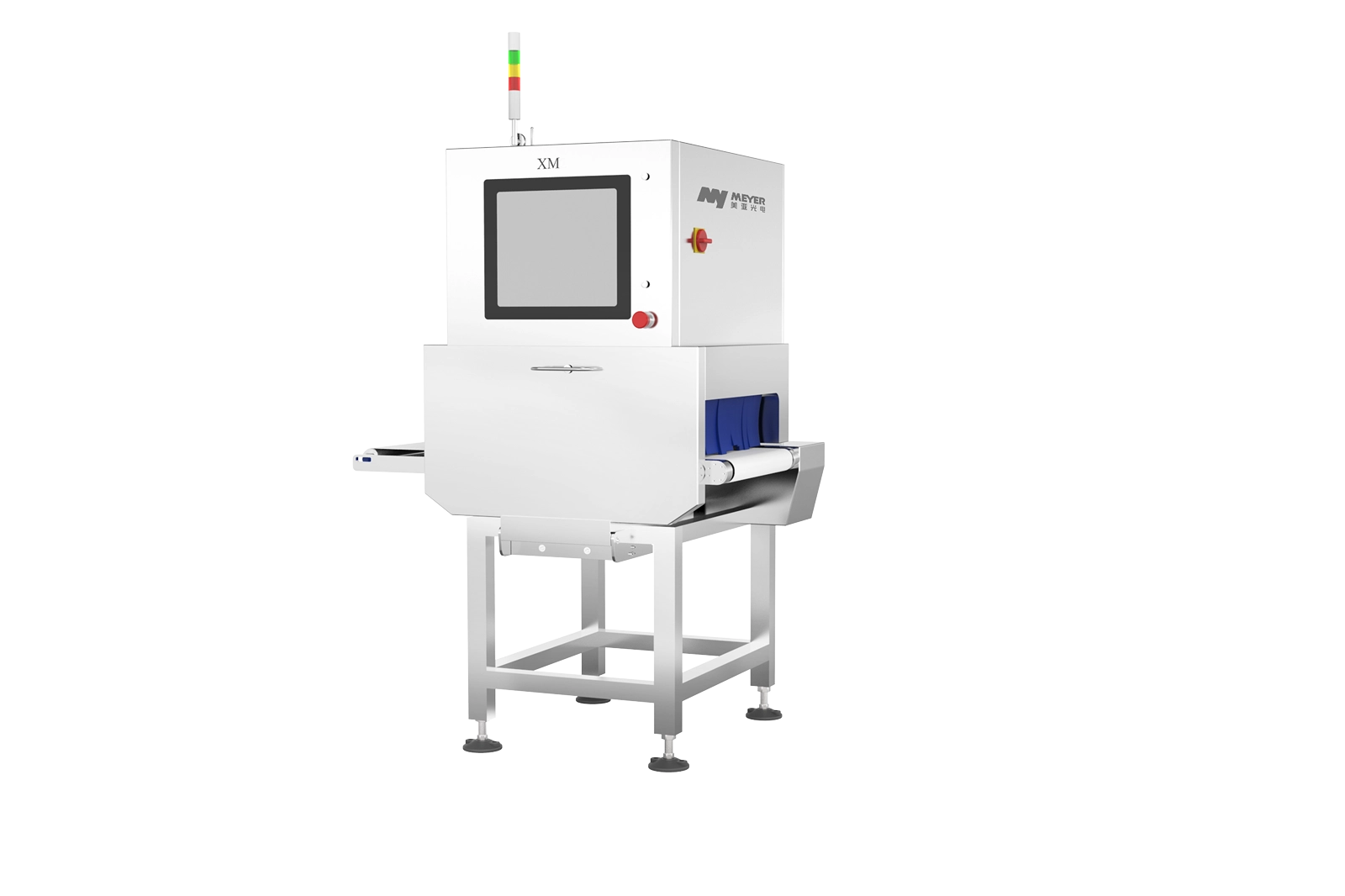

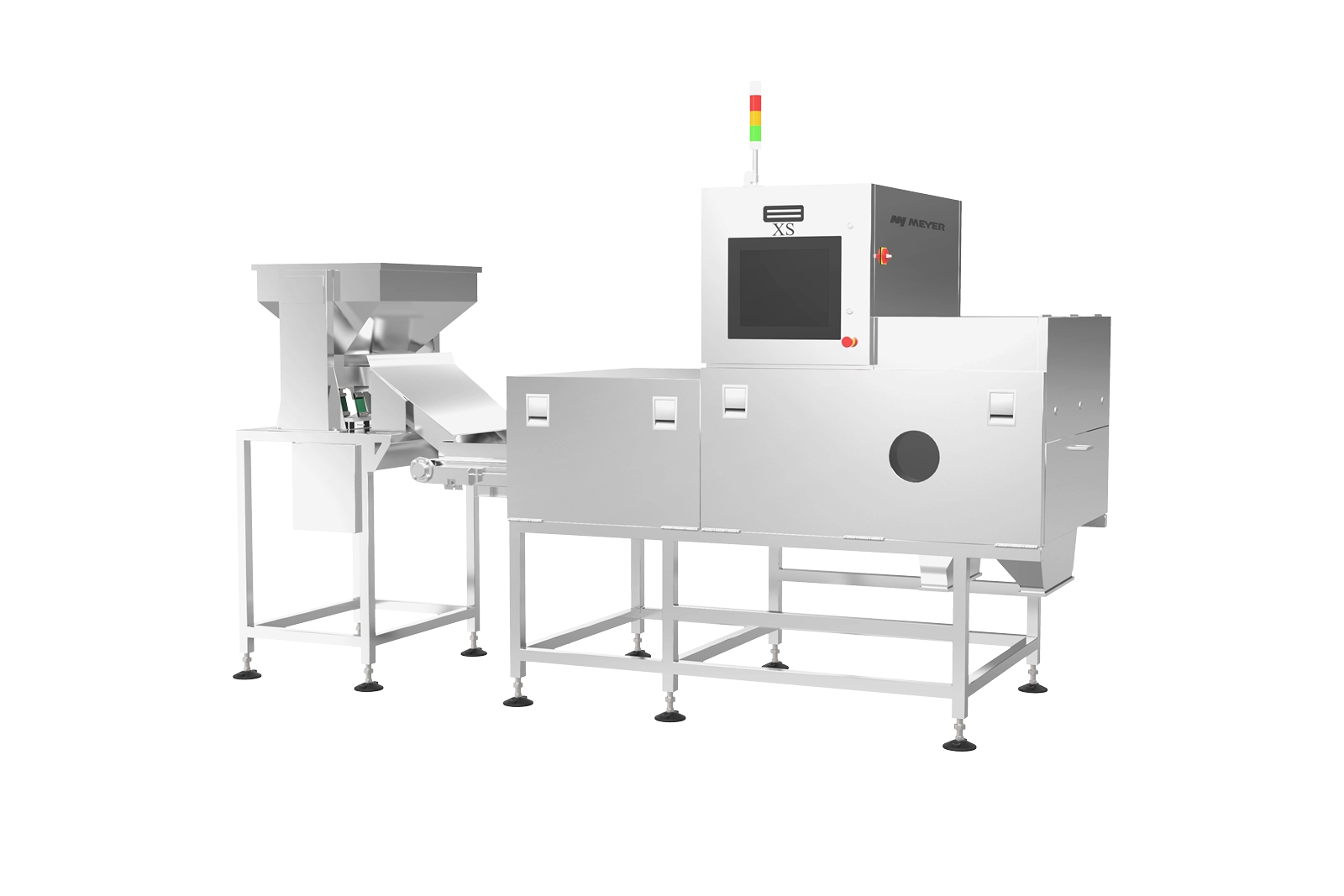

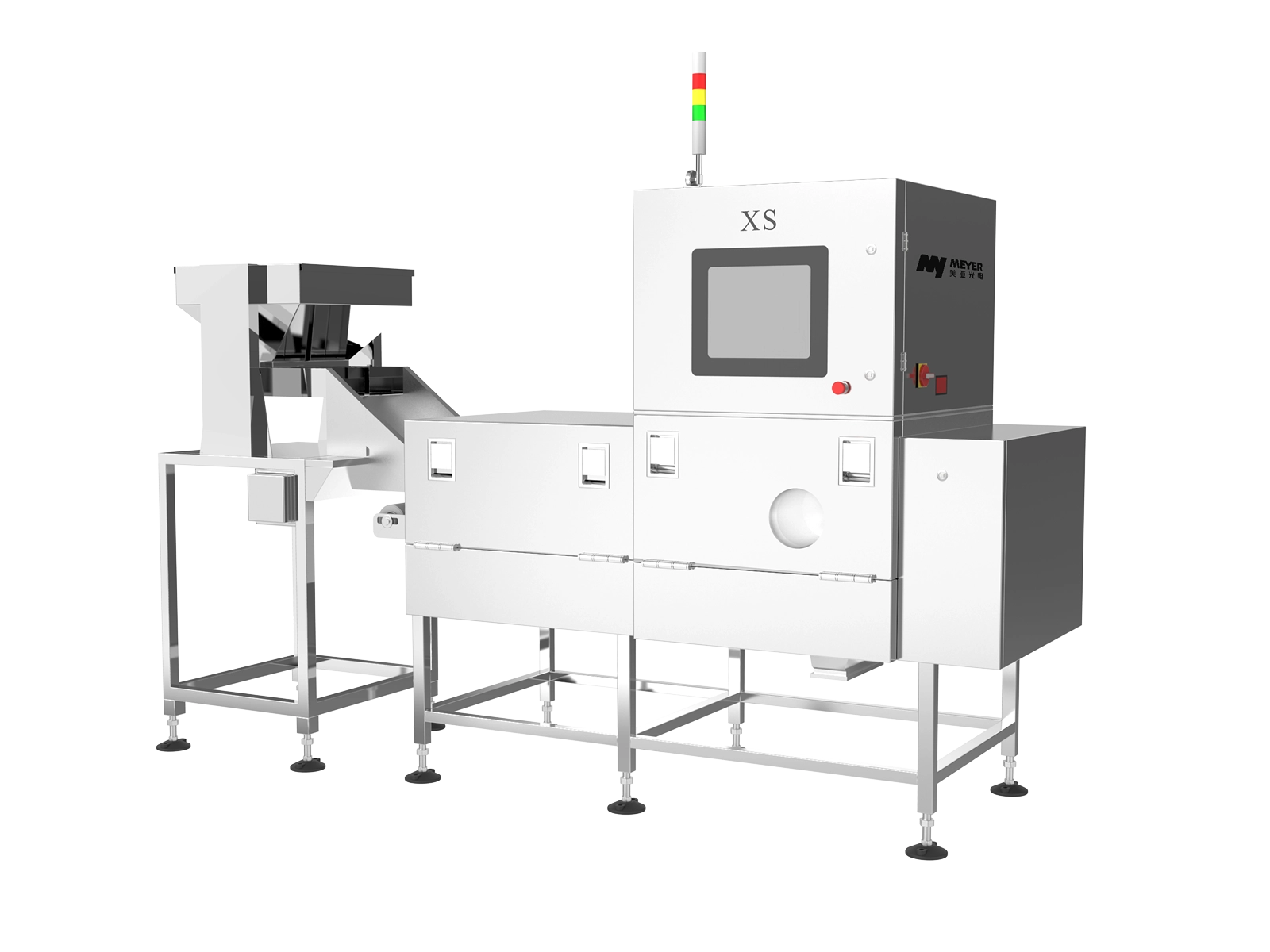

The MEYER XS X-ray detector has been designed for precise inspection of bulk products to identify hidden defects and unwanted contaminants. It effectively detects foreign objects such as glass, metal, stones, and ceramics that may pose a risk to food safety. The system is also capable of identifying internal defects invisible to the naked eye, including unripe, damaged, or hollow nuts, fruits, and seeds. Thanks to high precision detection, potential hazards can be eliminated without unnecessary product loss. Stable and high-speed operation ensures efficient quality control while preserving product integrity.

- High-density contaminant detection: The detection system accurately identifies foreign objects such as glass, metal, stones, and ceramics, even when their shape or appearance is similar to the inspected product. By analyzing internal structure and material density, the system can detect elements that remain undetected by traditional inspection methods.

- Operator and product safety: The MEYER XS X-ray detector is engineered with full operational safety in mind. X-ray radiation levels are strictly controlled and completely safe for both operators and inspected food products, with no impact on structure, taste, or nutritional value. The enclosed design and integrated safety systems ensure reliable and secure operation.

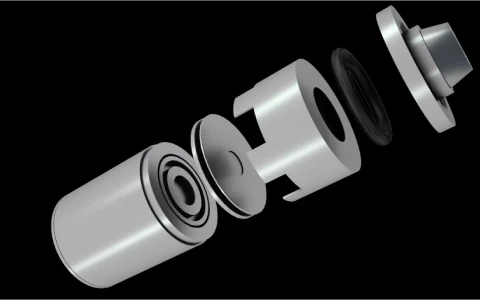

- Fast and precise defect separation: Maglev ejectors enable rapid and highly accurate removal of detected defects and foreign objects without disrupting the production flow. High response frequency and precise control ensure stable performance even at high throughputs, minimizing product loss and reducing the risk of damage.

Specifications

Model:

MY8045-60XSChutes:

Throughput:

t / hSorting accuracy:

99.99 %Power:

2 kWPower Voltage:

AC 180~240 V / 50HzAir source pressure:

MPaWeight:

950 kgDimensions:

3450 x 1320 x 2370 mmMaterial sorting samples and applications

Our solutions are based on modern technology

We will help you on every step

Pre-Sale Service

- Consultation on selecting the optimal optical sorter tailored to your needs.

- Support in integrating the machine with existing production lines.

- Assistance in designing new lines with the sorter as a key component of the installation.

- Material testing at our center – with the opportunity to attend and observe the process live.

- Comprehensive technical consultations to ensure optimal implementation and maximum efficiency

After Sale Service

- On-site service with quick response times and full commitment.

- Warranty including free inspections and maintenance.

- Consulting support for device usage and optimization.

- Individual service documentation ensuring a complete service history.

Optical sorting solutions

Frequently Asked Questions

Do I have any guarantee on Meyer products?

The 5-year guarantee covers all material and production defects in Meyer products.

Is the support available in all EU countries?

Content goes here ..