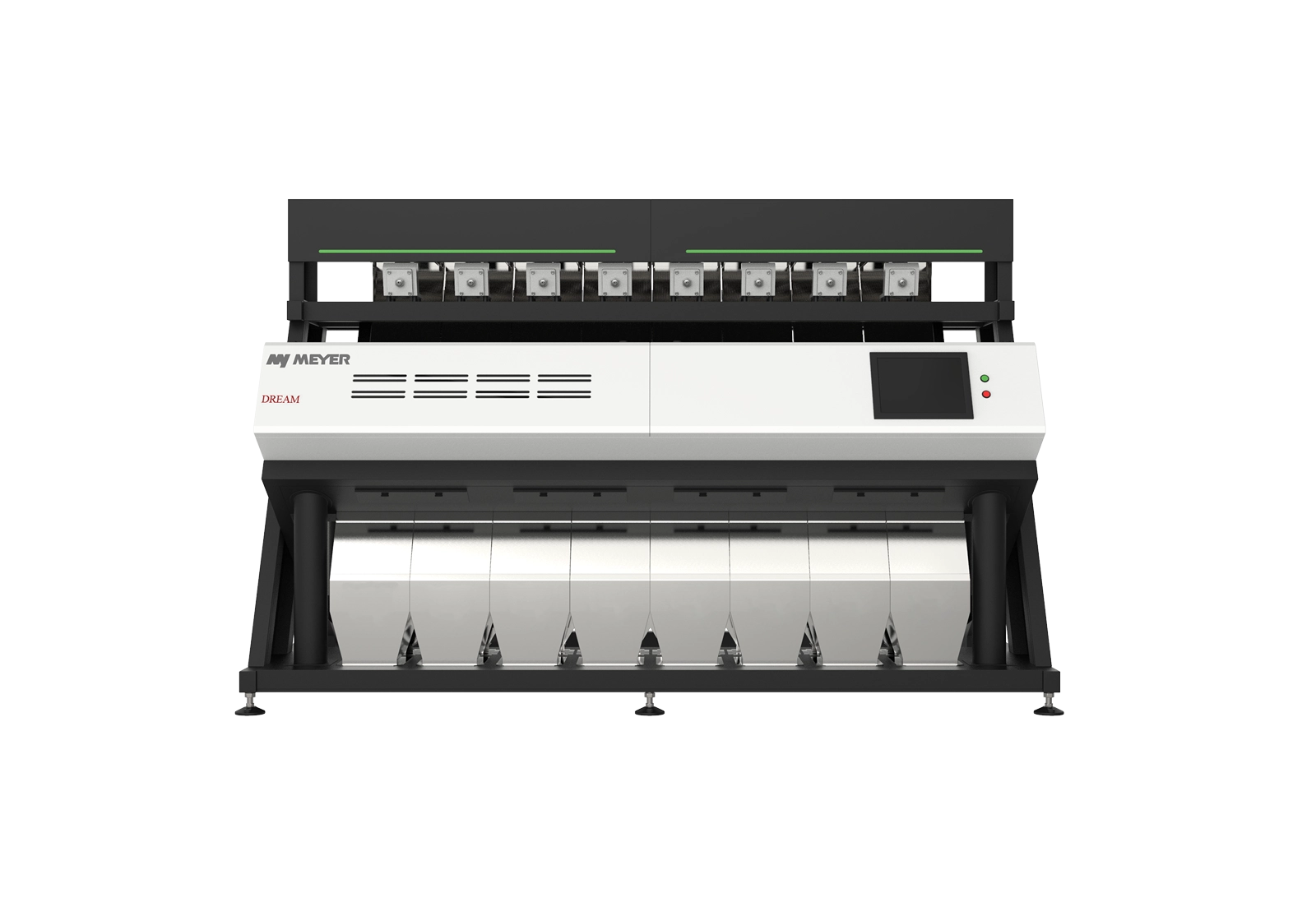

Chute Color Sorters

Discover the quality brought by MEYER chute color sorters. This solution enhances the quality and efficiency of your production line through precise color sorting of materials. Thanks to state-of-the-art technology, they significantly increase the value of processed raw materials, minimizing waste and maximizing productivity. Perfectly suited for the food, recycling, and agricultural industries, where high material purity is crucial for further processing. High throughput allows for efficient processing of small fractions, ensuring reliability and repeatability of the process. Intelligent algorithms analyzing the color of the material enable effective removal of contaminants and undesirable fractions. This modern and reliable solution is ideal for companies that prioritize quality and precision.

Discover Our Range of Chute Color Sorters

Improve Product Quality and Increase Throughput

Chute Color Sorters

Our chute color sorters are a versatile solution, ideal for the recycling industry and the food and agricultural sectors. In recycling, they efficiently separate plastic fractions, glass, and metals by color, increasing material value and facilitating further processing. In the food and agricultural industries, they excel at sorting grains, seeds, nuts, spices, and dried fruits, removing impurities and unwanted fractions. Precise color separation enhances efficiency, improves raw material quality, and reduces waste. With advanced optical technologies and AI Deep Learning systems, our sorters ensure reliability and efficiency, meeting the demands of even the most challenging production and recycling processes.

See sorting samplesHow can you use optical sorting solutions?

Our clients’ stories

Frequently Asked Questions

Can color sorters be customized to meet specific customer needs?

Yes, our color sorters are always tailored to the individual needs and capabilities of the customer. The process begins with conducting tests in our research center to develop the optimal sorting scheme. We then design solutions that are adapted to specific requirements and production capabilities, ensuring maximum effectiveness and efficiency.

Can chute color sorters be integrated into existing production lines?

Yes, chute color sorters can successfully be integrated into existing production lines. This requires proper adjustment of the material transport system and sorter configuration to ensure optimal performance. Our team of specialists provides assistance at every stage – from technical analysis to implementation and calibration. As a result, integration is seamless, and the sorter effectively supports the production process, enhancing sorting quality and efficiency.

Can MEYER color sorters be used in environments with high dust levels?

MEYER color sorters can be used in environments with high dust levels, but certain factors need to be considered regarding their operation in such conditions. In such environments, automatic wipers need to clean the sorter’s windows more frequently, which can lead to increased energy consumption and shorter operating cycles before a maintenance break is required. As a result, the continuity of the sorter’s operation may be slightly reduced, and its performance might decrease marginally. However, our sorters are designed to maintain high sorting quality even in challenging conditions. While this requires additional monitoring, the systems remain reliable and effective over the long term.