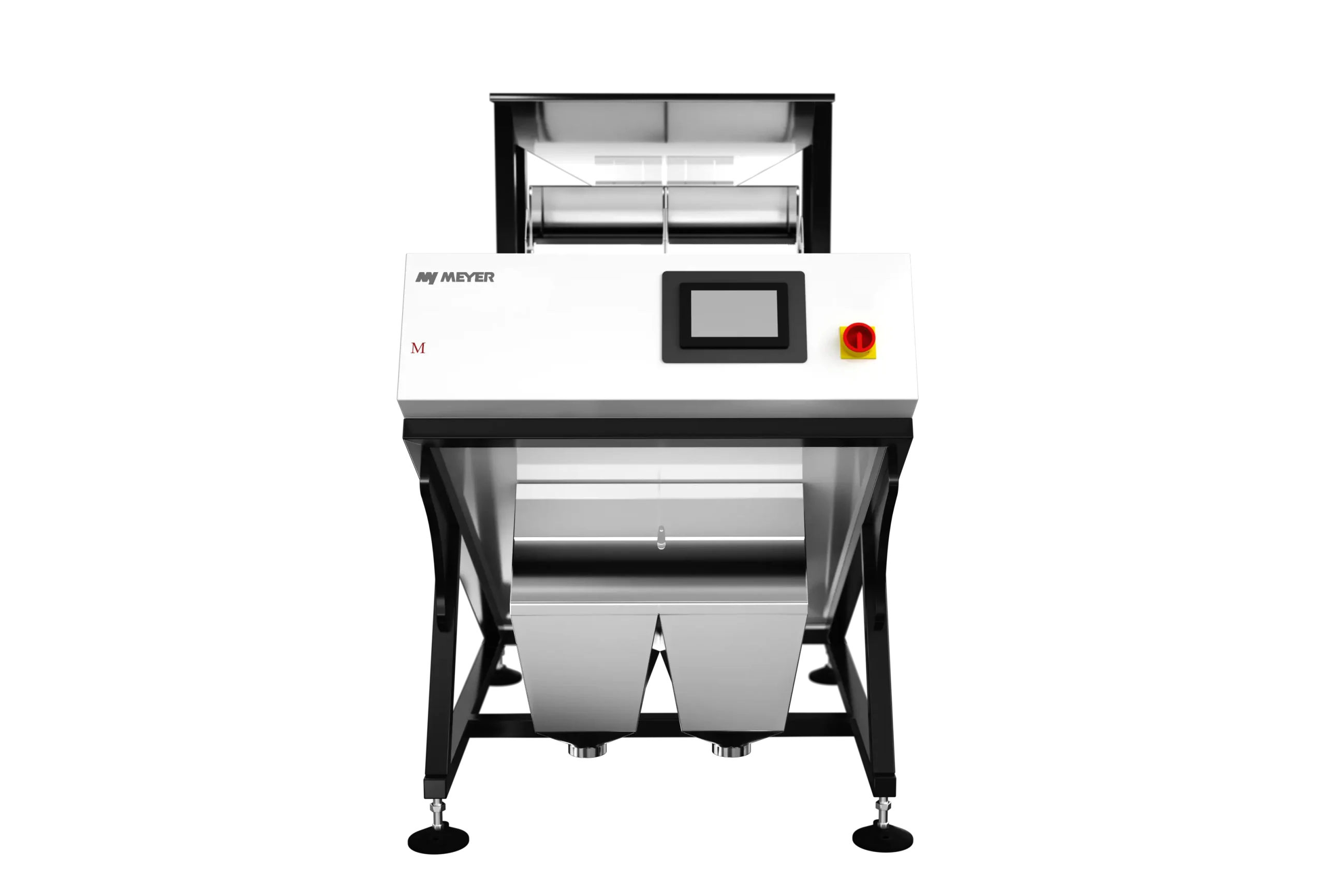

Chute Polymer Sorters

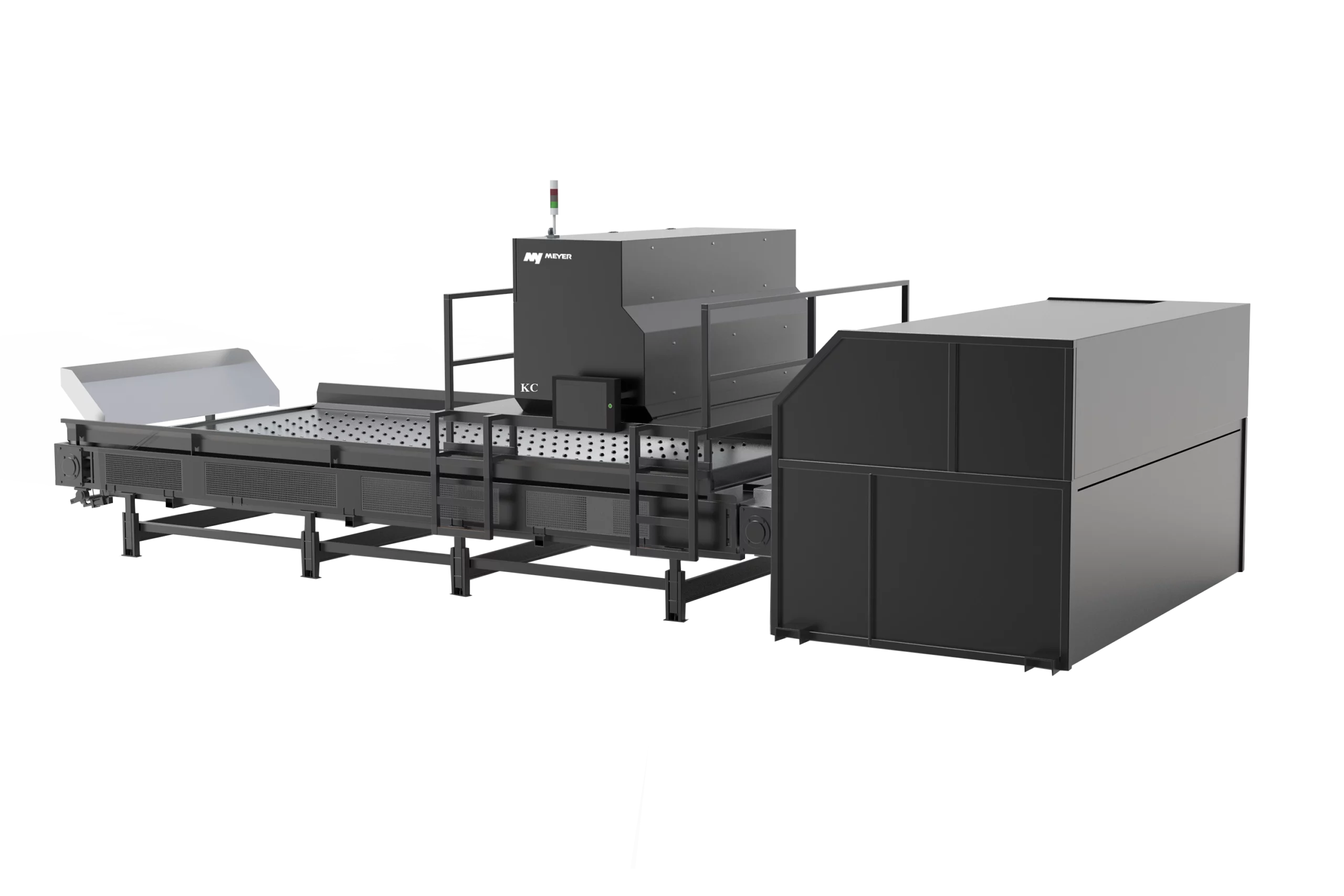

CI – Polymer Sorter

Sorter details

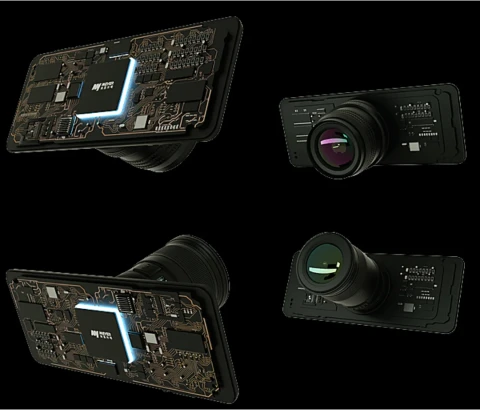

Meyer Technology

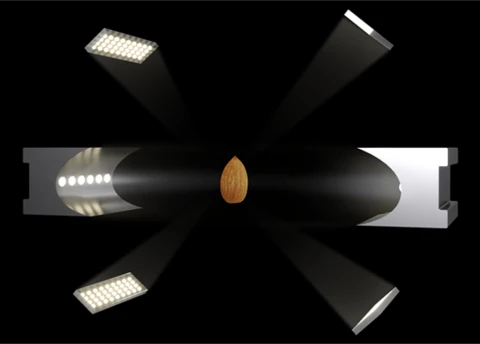

MEYER CI enables precise separation of different types of plastics, ensuring material purity and consistency at every stage of production. Using infrared technology and multispectral material analysis, the system can distinguish PET, PE, PP, and PVC even when there are no visible differences between them. As a result, the processed material retains its properties, and PET flakes can meet food-grade standards required for food packaging production.

- Accurate polymer identification:

InGaAs technology combined with multispectral infrared analysis allows for precise detection and separation of various plastic types, such as PET, PE, PP, and PVC, even when their appearance, color, or transparency is very similar. The system analyzes the material’s structure and composition in real time, minimizing the risk of errors and ensuring a clean material stream. This makes it possible to produce uniform, high-quality plastic granulates or flakes that meet stringent industry standards. - Three-dimensional material analysis:

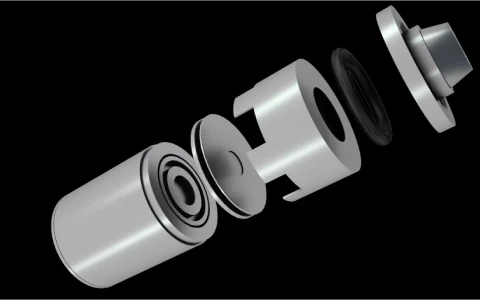

The system uses 3D material reconstruction, enabling each item to be accurately mapped in terms of shape, size, color, and material type. Precise positioning allows Maglev ejectors to remove unwanted elements with exceptional accuracy, minimizing material loss. This ensures a consistent material flow, improves sorting repeatability, and effectively prepares the material for subsequent production stages. - High-speed Maglev ejectors:

The ejectors respond almost instantaneously, precisely removing unwanted plastics from the material stream. This ensures uninterrupted sorting, minimizes material losses, and allows for a more concentrated waste fraction.

Send inquiryTest center

Specifications

Model:

CI3 180CI-GY / 6SXZ-180CI-GYChutes:

3Throughput:

0.2-0.7 t / hSorting accuracy:

99.99 %Power:

4.5 kWPower Voltage:

AC 180~240 V / 50HzAir source pressure:

0.6~0.8 MPaWeight:

1400 kgDimensions:

1628 x 2030 x 1700 mmOptical sorting use cases

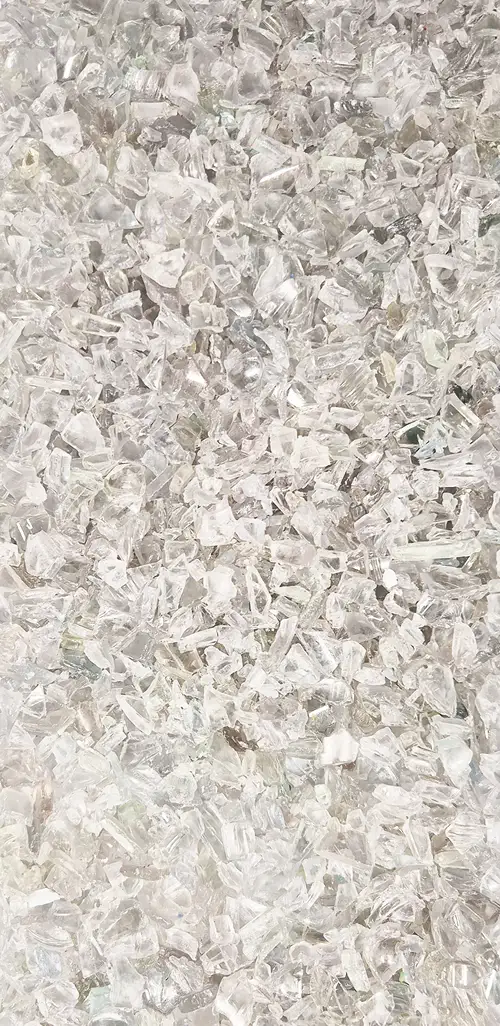

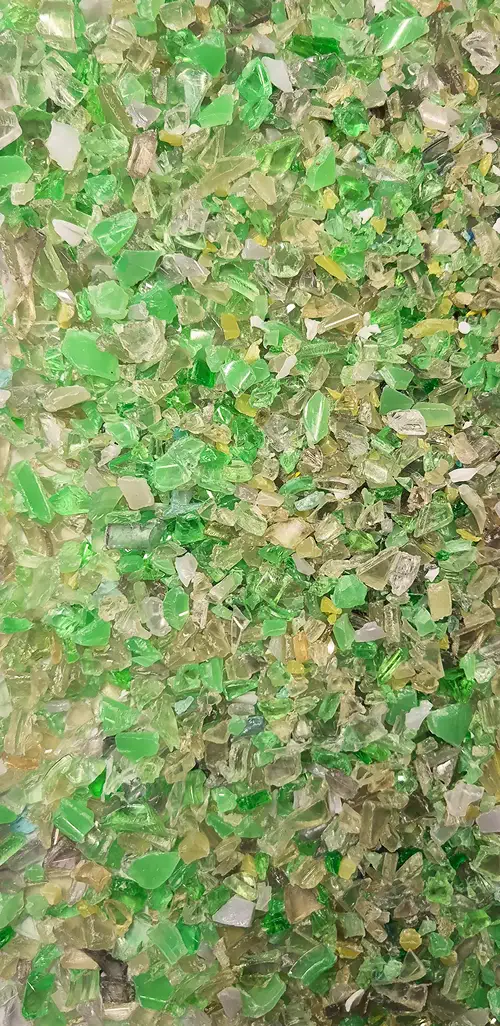

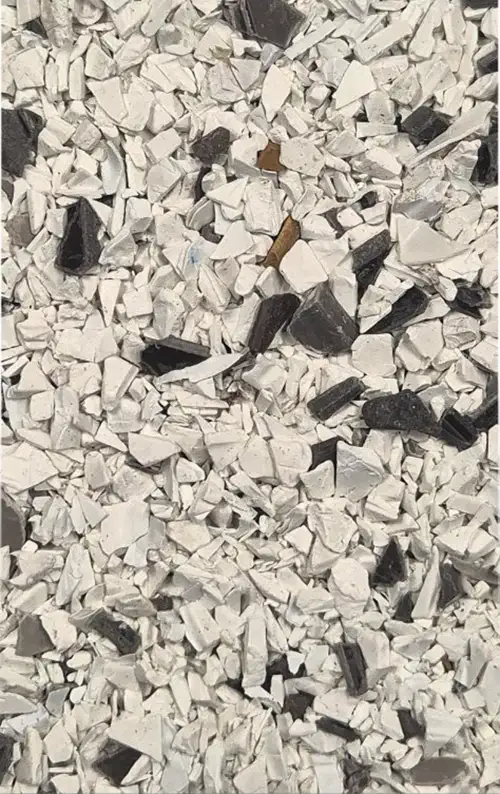

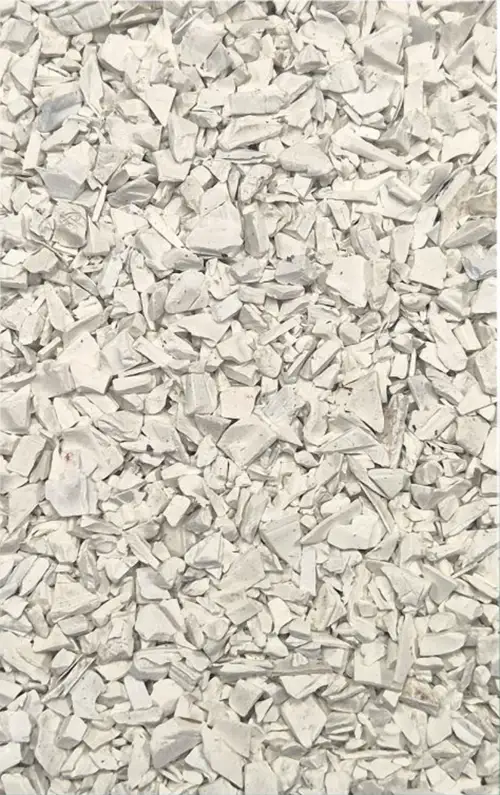

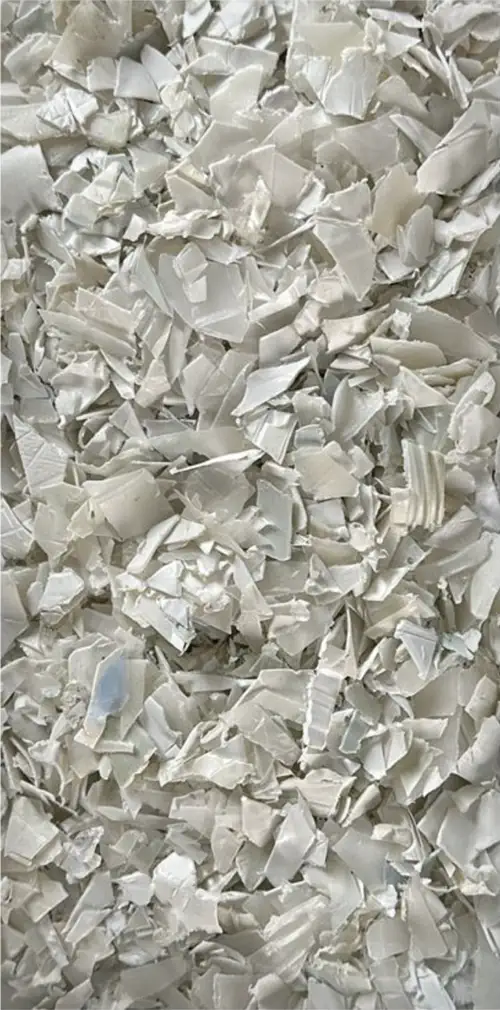

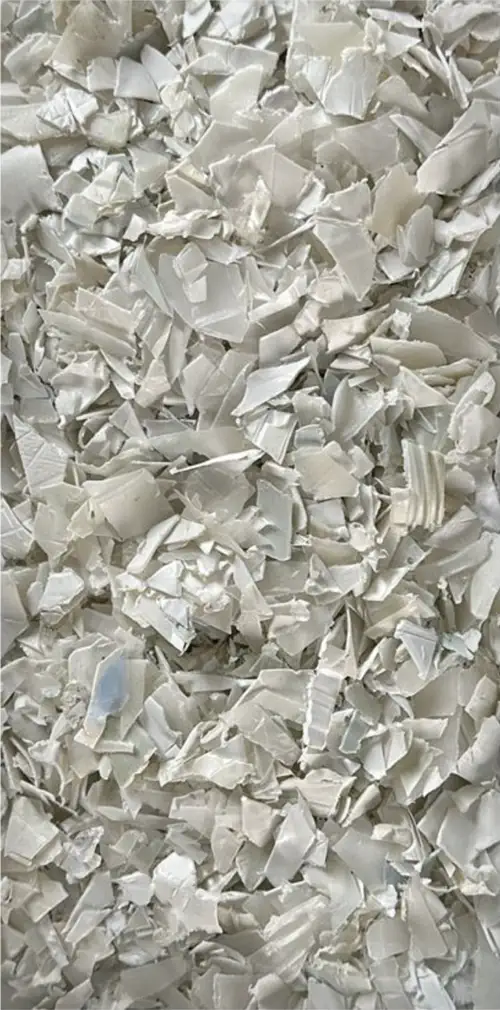

Material sorting samples and applications

INPUT

ACCEPT

REJECT

Product features

Our solutions are based on modern technology

Our services

We will help you on every step

Pre-Sale Service

- Consultation on selecting the optimal optical sorter tailored to your needs.

- Support in integrating the machine with existing production lines.

- Assistance in designing new lines with the sorter as a key component of the installation.

- Material testing at our center – with the opportunity to attend and observe the process live.

- Comprehensive technical consultations to ensure optimal implementation and maximum efficiency

After Sale Service

- On-site service with quick response times and full commitment.

- Warranty including free inspections and maintenance.

- Consulting support for device usage and optimization.

- Individual service documentation ensuring a complete service history.

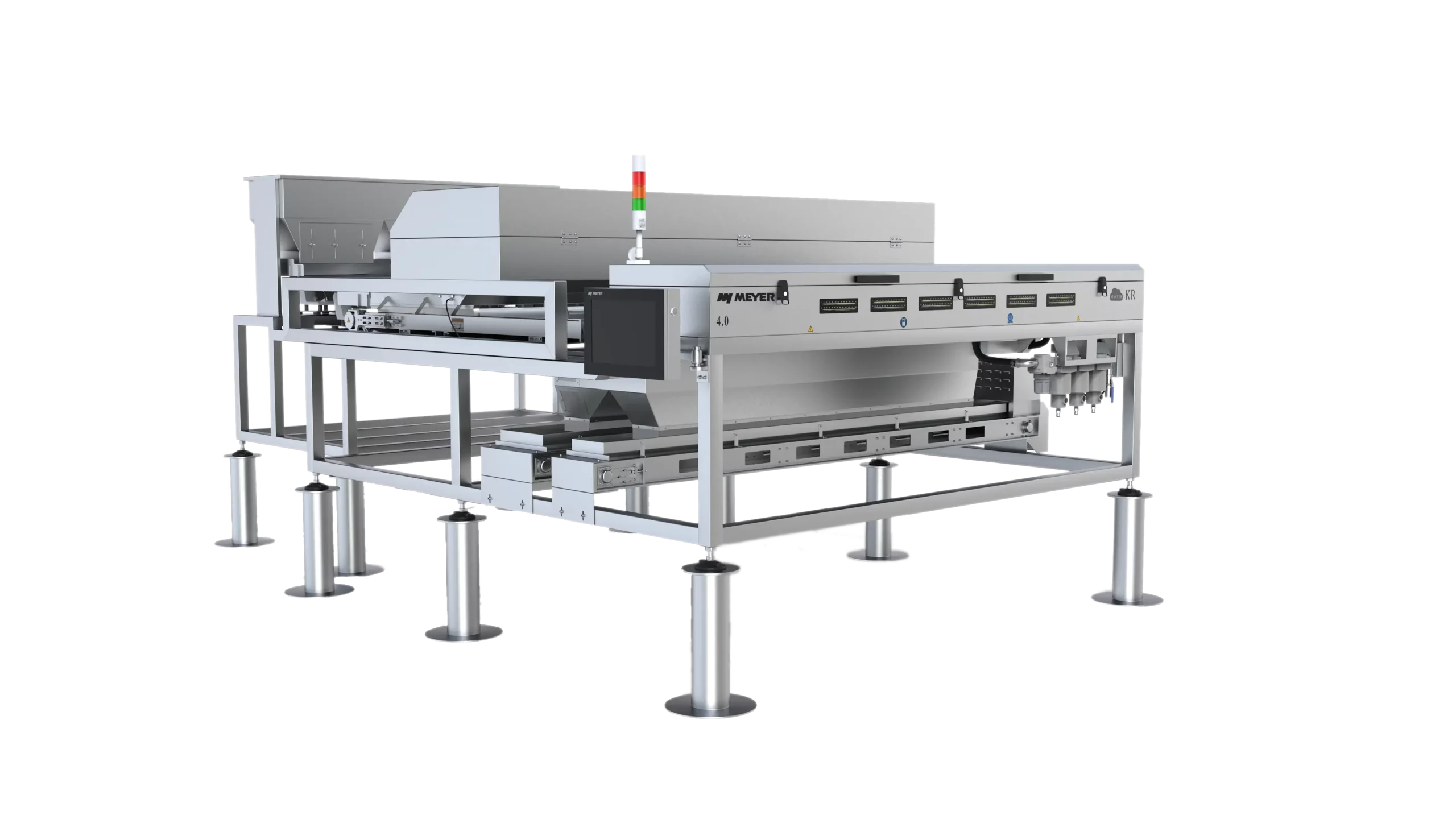

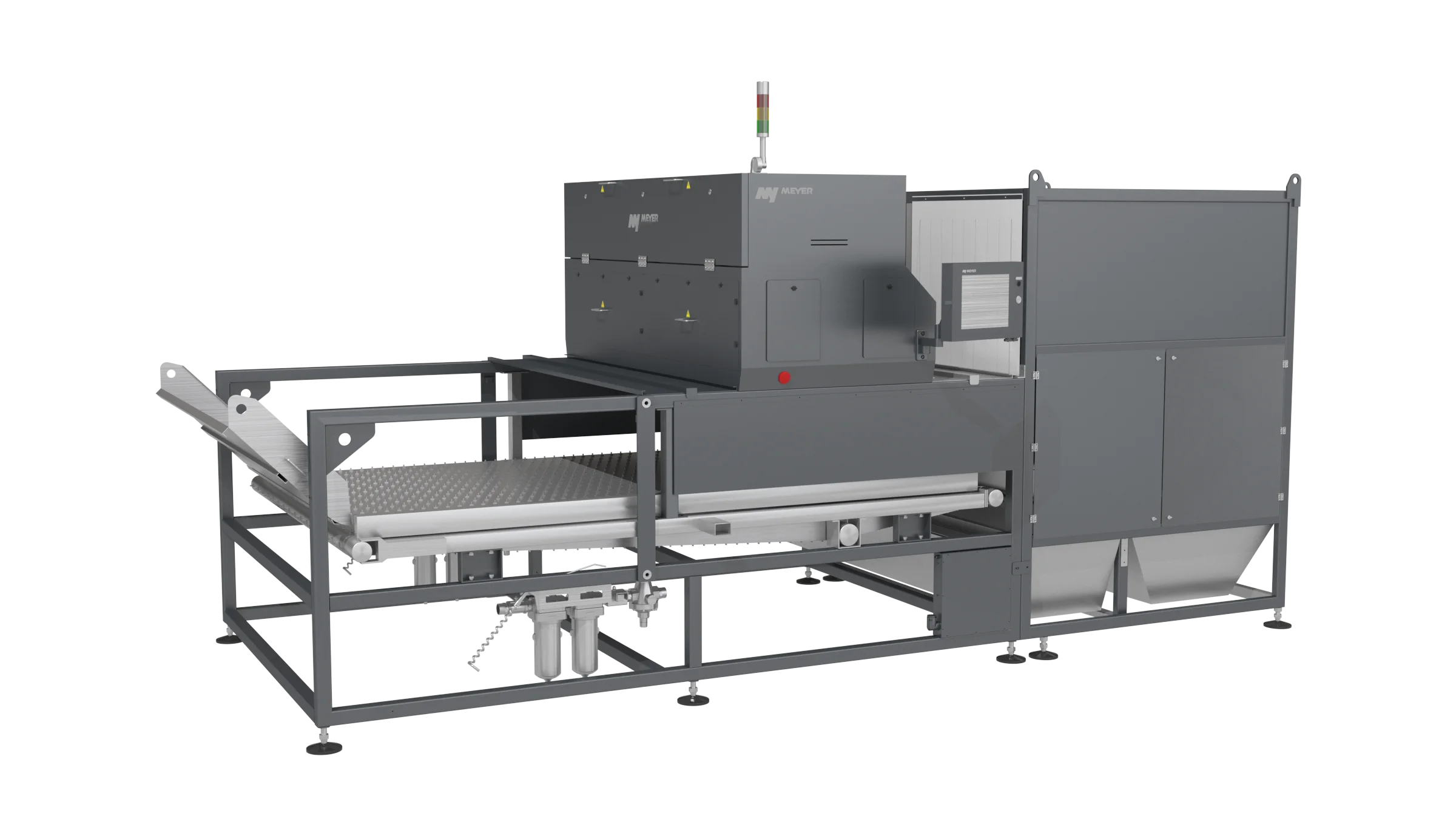

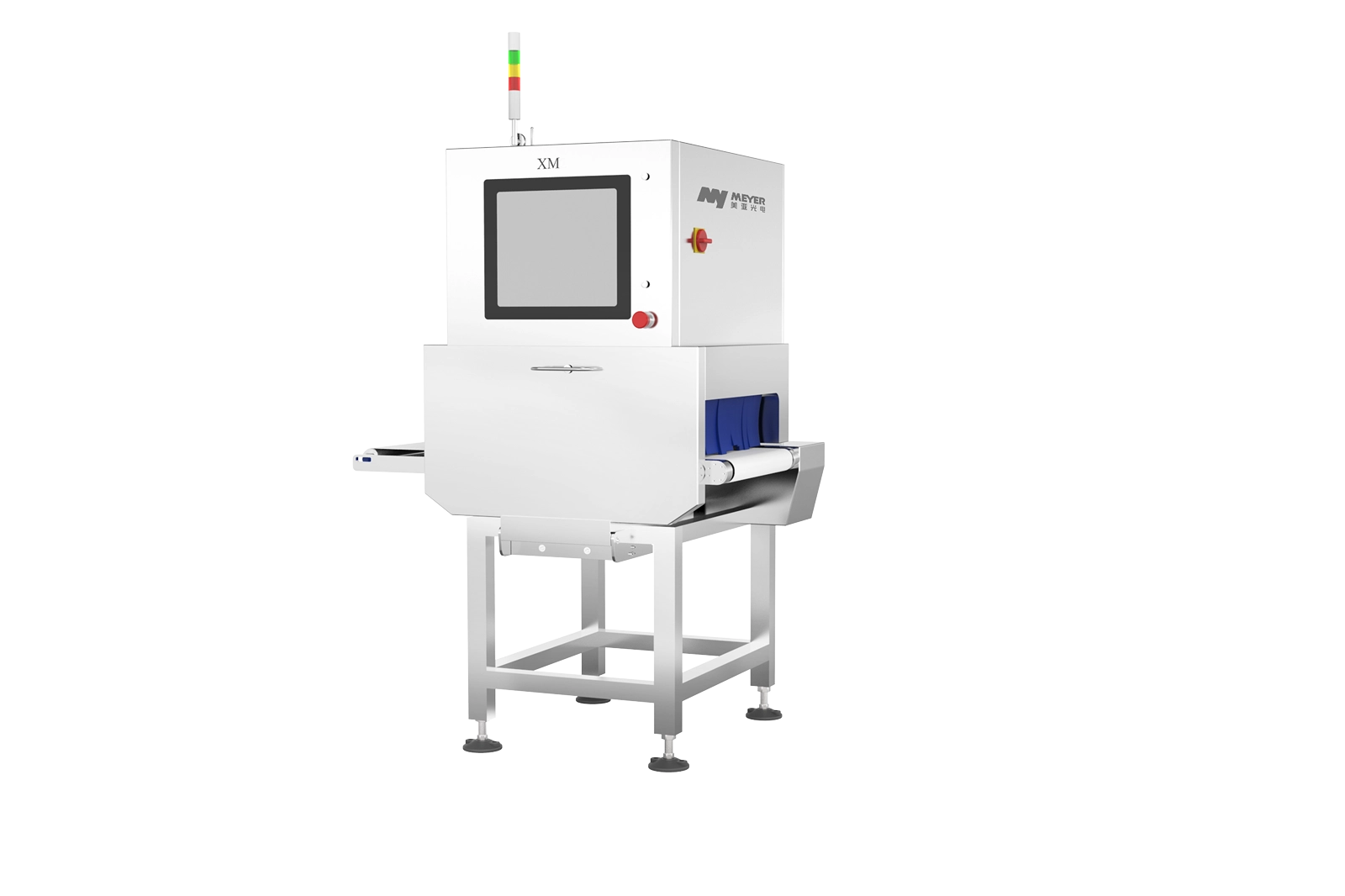

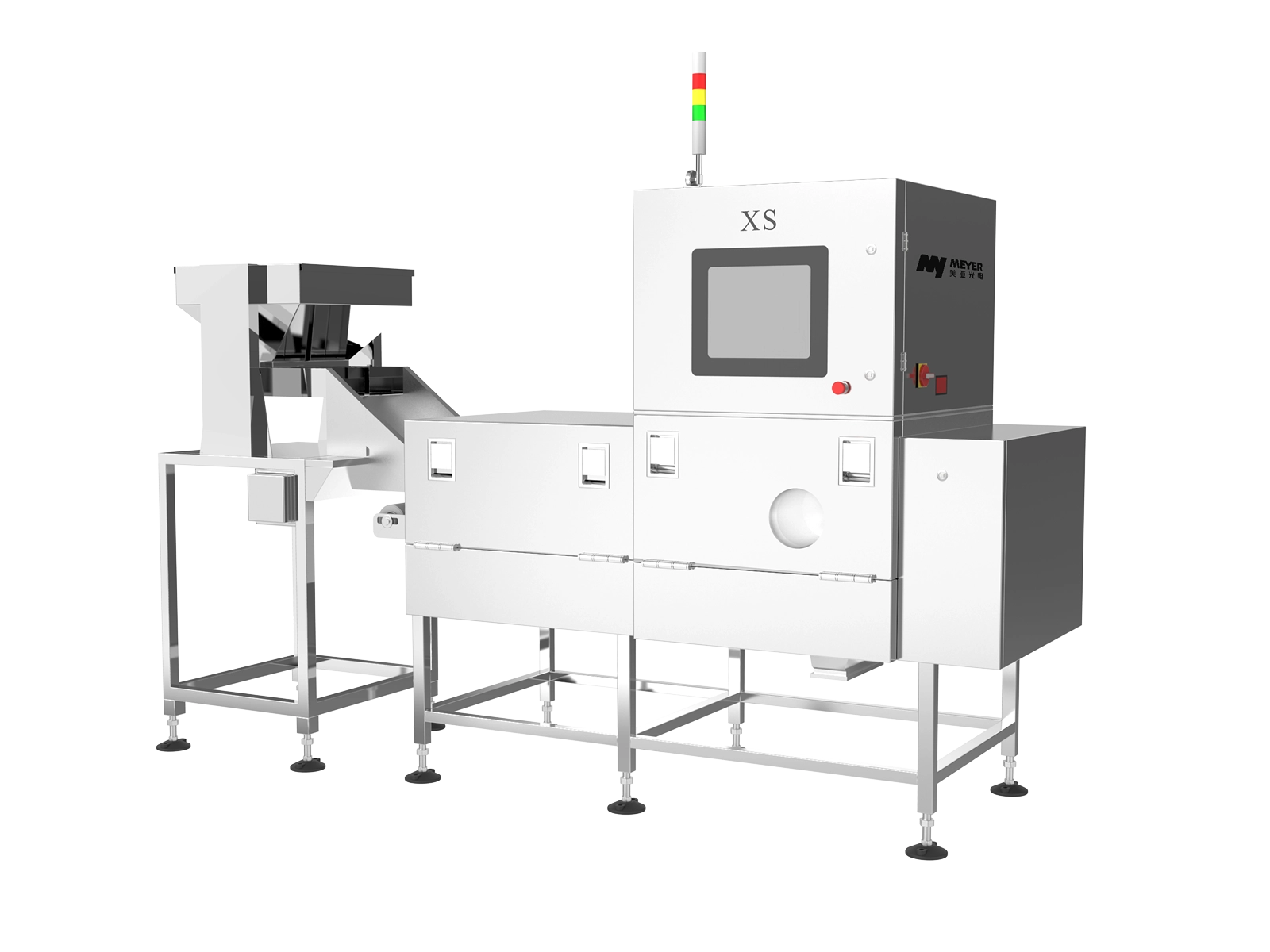

Related products

Optical sorting solutions

FAQ

Frequently Asked Questions

Do I have any guarantee on Meyer products?

The 5-year guarantee covers all material and production defects in Meyer products.

Is the support available in all EU countries?

Content goes here ..

Contact Us