1. Labor Shortages and Automation in Food Processing

1.1 The Impact of Labor Shortages on Production

Labor shortages in the food processing sector happen for several reasons. These include an aging workforce and fewer people wanting agricultural jobs. Strict immigration policies also play a role.

Additionally, it is hard to attract young talent. Many workers are moving to less demanding jobs, which means there are fewer skilled people to take their place. This has led to delays in production and problems with the supply chain. Workers are under more pressure, so we need to find solutions that can grow.

These shortages mean reduced production capacity, increased workloads, and potential quality issues. Companies are dealing with high turnover and absenteeism, which adds more strain on workers. This affects product availability and raises concerns about the quality and consistency of food reaching consumers.

1.2 Automation and Optical Sorting Technology: A Solution to Labor Challenges

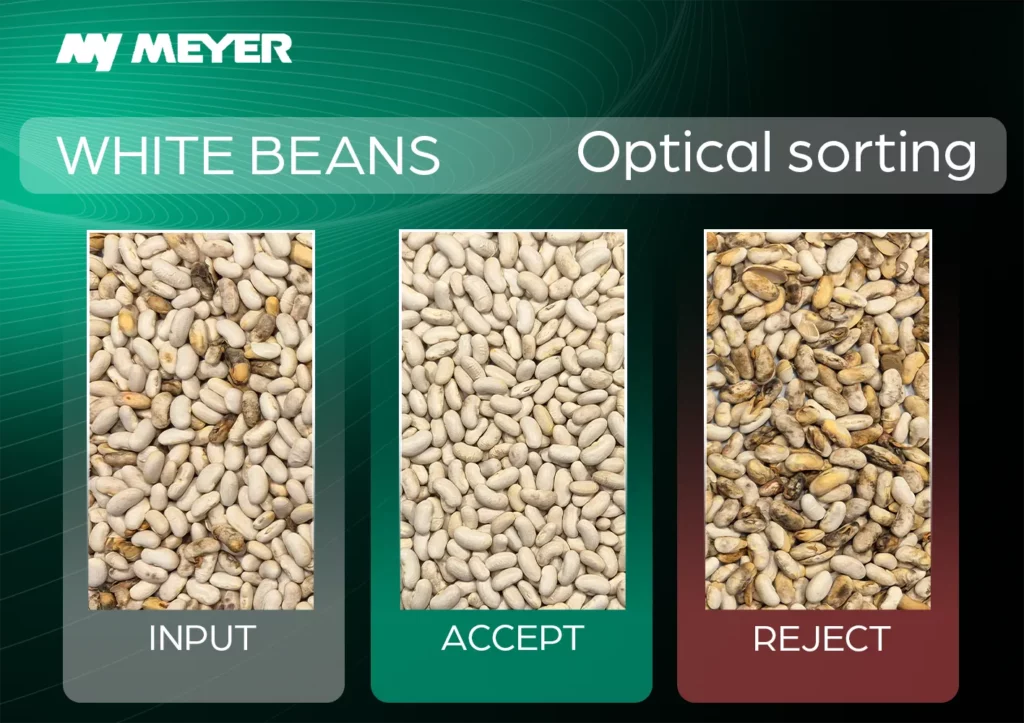

To address labor shortages, food processing companies are using more automation, with optical sorting technology leading the way. Optical sorting machines use advanced cameras, sensors, and smart algorithms to identify and sort products by color, shape, and size, and even material density (using InGaAs cameras). Additionally, X-ray detection allows for the removal of foreign objects from the sorted materials. This method is particularly useful when there are small color differences between foreign objects and the sorted material, as well as for packaged food or products in cans or jars.These machines can do complex sorting tasks that would need many workers, which helps reduce labor needs.

By replacing manual sorting with automated systems, companies can boost productivity and keep quality consistent. Workers who used to do repetitive sorting can take on higher-value roles, such as quality assurance or machine supervision. This change not only improves efficiency but also makes food processing jobs more appealing by giving workers opportunities to learn technical skills and take on more meaningful roles. Automation and food industry automation are changing the dynamics of the workforce in the food industry.

2. Ensuring Product Quality and Food Safety

2.1 The Importance of Quality Control in 2025

Product quality and food safety are crucial for both consumers and regulators in 2025. Consumers want fresh, clean products, while government agencies enforce strict food safety regulations to protect public health. Food processing companies face pressure to maintain consistent quality to avoid costly recalls and protect their brand reputation.

Contamination incidents can seriously harm a company’s image and lead to financial losses, making investments in food safety technology, food safety compliance, and strict quality protocols very important. Trust is critical, and even a single quality failure can damage consumer loyalty for a long time.

2.2 How Optical Sorting Technology Enhances Food Safety?

Optical sorting technology helps maintain product quality by removing defective items and foreign materials from the production line. These machines can detect and remove contaminants like stones, pieces of plastic, glass, or metal, as well as plant matter that may enter the food supply. They also identify discoloration, mold, blemishes, and other defects, ensuring that only high-quality products reach consumers.

Advanced optical sorters can even check the material density, detecting contaminants that may be invisible to the human eye. By removing defective items early in the process, companies can follow food safety regulations and reduce the risk of recalls. This proactive approach also builds consumer confidence by ensuring products are consistently safe and high-quality. Sensor-based food sorting, optical inspection systems, and automated food inspection strengthen food quality assurance and help meet food safety protocols.

X-ray detectors play a crucial role in ensuring food safety by identifying foreign objects like glass or metal fragments in products. They are particularly effective during the final stages of production, where they can inspect packaged food items such as packs of frozen vegetables and fruits, canned goods, or jarred products. These machines can automatically remove defective packages, ensuring that food safety standards are met and consumer trust is preserved.

3. Sustainability and Waste Reduction

3.1 Sustainability Challenges in the Food Industry

The food processing industry is under growing pressure to adopt sustainable practices due to rising awareness of environmental issues. The sector has a big impact on the environment through waste, energy use, and carbon emissions. Consumers are demanding transparency and sustainability, and companies that don’t meet these expectations risk losing customers to more eco-friendly competitors.

To meet sustainability goals, companies must minimize waste, use resources wisely, and reduce energy consumption. Failing to do so may lead to difficulties in meeting the expectations of consumers who prefer companies that take responsibility for the environment.

3.2 Optical Sorting’s Contribution to Waste Reduction and Sustainability

Optical sorting technology is key to promoting sustainability in the food industry. One major benefit of optical sorters is their accuracy. Manual sorting often leads to throwing away food that could still be used. Optical sorters can better distinguish between truly defective items and those that are acceptable, reducing food waste.

Optical sorters are also energy-efficient. Compared to older equipment, modern optical sorting systems use less energy, which helps reduce carbon footprints. By minimizing waste and making better use of raw materials, optical sorting helps lower the environmental impact.

This accuracy and efficiency not only improve sustainability but also help reduce costs by preventing product loss. Food processing technology includes tools for sanitation and quality control. These tools help make operations more sustainable. They also reduce cross-contamination and extend the shelf life of food products.

4. Rising Operational Costs

4.1 Cost Pressures on Food Processing Companies

Food processing companies are dealing with higher operational costs due to rising prices for raw materials, energy, and transportation. Recent disruptions in the food supply chain have caused price instability, making cost control harder. Inflation also adds to the difficulties, making it challenging to stay profitable.

To remain competitive, companies need ways to reduce costs without sacrificing product quality. Balancing these needs is tough, and companies are always looking for new ways to save money and maintain efficiency.

4.2 How Optical Sorters Improve Cost Efficiency

Optical sorting technology helps reduce costs by improving processing efficiency and reducing the need for manual labor. These machines can handle large volumes of food with greater speed and accuracy than human workers, keeping production fast and reducing costs. In addition to labor savings, optical sorters reduce waste by accurately removing defective items, which means fewer raw materials are wasted. The savings from reduced labor costs, better yields, and less waste all contribute to greater profitability. Investing in advanced sorting technologies and food processing equipment can help companies manage rising costs while keeping manufacturing efficient.

5. Adapting to Changing Consumer Preferences

5.1 Trends in Consumer Preferences for 2025

In 2024, consumers are focusing more on health, transparency, and sustainability. They want foods that are organic, minimally processed, and free from artificial additives. There is also a higher demand for transparency in how food is sourced and produced, as consumers want to know that the products they buy are safe, healthy, and responsibly made.

Another trend is the demand for specialty products, like gluten-free, vegan, and non-GMO options. This change requires food processors to meet diverse consumer needs while staying efficient.

5.2 Leveraging Optical Sorting Technology to Meet Consumer Demand

Optical sorting technology helps food companies meet changing consumer demands. By ensuring that only high-quality, clean products reach the market, optical sorters help produce healthier foods that match consumer preferences. The technology also supports the handling of specialty items, like organic or allergen-free foods, with less risk of cross-contamination.

Optical sorting also helps make production more transparent. By monitoring product quality at each stage, companies can give consumers the confidence they need regarding food safety. This transparency builds customer satisfaction and loyalty. By using machine vision in the food industry, food safety audits, food safety testing, and Hazard Analysis and Critical Control Points (HACCP), companies can meet consumer expectations and consistently deliver high-quality products.

Conclusion

Optical sorting technology helps solve many challenges in the food processing industry. It tackles labor shortages and ensures high product quality and safety.

It also supports sustainability by reducing waste. Additionally, it lowers costs and helps companies adjust to changing consumer preferences. As the industry evolves with rising costs, sustainability pressures, and labor issues, optical sorting technology is becoming crucial for staying competitive and ensuring long-term growth.

By using optical sorting solutions, food processors can prepare for the future. They can meet regulatory and consumer standards. This also helps them support environmental goals.

Throughout 2025, advanced optical sorting technology will strengthen operations and help companies succeed in an ever-changing market. Integrating food preparation, automated food inspection, and food packaging systems, supported by high-speed conveyor belts, will help ensure foods are processed efficiently while reducing the risk of contaminated food reaching consumers.