Packaging made from PCR nowadays needs to meet a growing number of criteria. To satisfy market expectations, primarily in the area of shredded plastic sorting by colour, ATUS entered into a partnership with MEYER. What has resulted from such synergistic collaboration between these innovation leaders?

ATUS AND MEYER – SYNONYMS OF QUALITY AND CUTTING-EDGE APPROACH

They say that ‘opposites attract’. This is especially true considering two companies with a vision that are boldly setting trends in their sectors and leveraging state-ofthe-art developments.

ATUS is the nation’s foremost recycler of HDPE packaging, having been in business for more than 20 years. The company reates turnkey solutions for the construction industry, as well as makes in-house HDPE regranulates for their customers operating in blow moulding, injection moulding and extrusion applications. Their mission is to be a quality leader in specialty recycled products (PCR) for the packaging and industrial sectors. The brand is committed to technological growth, eco-friendliness and advanced machinery.

And the latter has expanded over the past six months with another high-end piece of equipment – this time from MEYER, a manufacturer of the highest technology optical sorters and X-Ray inspection equipment. ATUS specialists saw particular potential in the optical sorter, i.e. CG.P Sorter, made by MEYER.

“Following a number of technological tests in our Test Center, it became clear that the full RGB vision systems, broadband LED lighting and the patented Maglev 3.0® and Target Positioning 3.0® defect rejection systems used in our equipment enabled ATUS to achieve the most satisfactory colour separation of HDPE PCR flakes among the solutions available on the Polish and European markets”, comments Piotr Okoń, Sales & Business Development Manager at MEYER Europe.

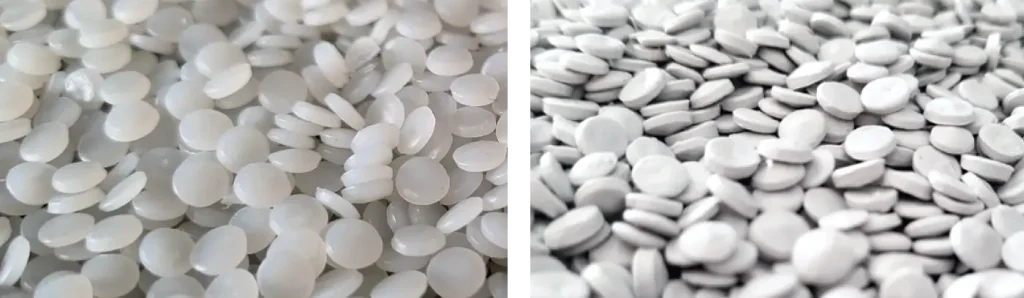

ATUS was keen to achieve precise colour detection and sorting of HDPE flakes, and thus to complete its range of PCR regranulates for blow molding, in white and natural variants. The machine meets these objectives to an overriding degree, both in terms of sorting quality and the yield of the final material fractions, as well as the sheer efficiency of the process. “We are satisfied with the performance of the MEYER CG optical color sorter. This machine has met our expectations in terms of the color separation process of PCR regrind, giving us the ability to recycle more HDPE waste, with less product loss, while maintaining stable, top-quality production. We are now able to supply top-grade PCR regranulates, the grade of which meets the requirements of many of our customers”, says Jakub Barnaś, owner and plant manager of ATUS Group.

THE ROLE OF THE OPTICAL SORTER IN RAW MATERIAL PROCESSING

In the modern market, it is the technology used to process the raw material that is of particular relevance. However, it is color separation that is very often used in the recycling of plastics. The business customer

will expect not only colored raw material, but also white or transparent flakes. And today, regranulates in different colors can be created without the use of dyes.

The question is: how can the most efficient sorting be carried out? The answer to this question is MEYER CG.P optical sorter, which allows plastic material to be segregated and divided into different colors to produce a final product with the desired color. Plus, it has a sorting capacity of up to 10 tonnes of input material per hour. Yet, the machine’s capabilities also extend beyond this. In fact, the sorter provides the

option of adjusting the intensity of the LED light source, which facilitates easy identification of even subtle color differences.

PARTNERSHIP THAT HAS YIELDED TANGIBLE RESULTS

The collaboration between the ATUS and MEYER brands, which started six months ago, included conceptual, implementation, assembly, programming and training work for the integration of the new sorter into existing processes.

As a result, MEYER has implemented another innovative project and ATUS has improved the production quality of post-consumer HDPE waste regrinds by extending its scope to include natural regranulate and white regranulate (apart from a mix of other colors, of course). That is what customers expect today.