Working Principles

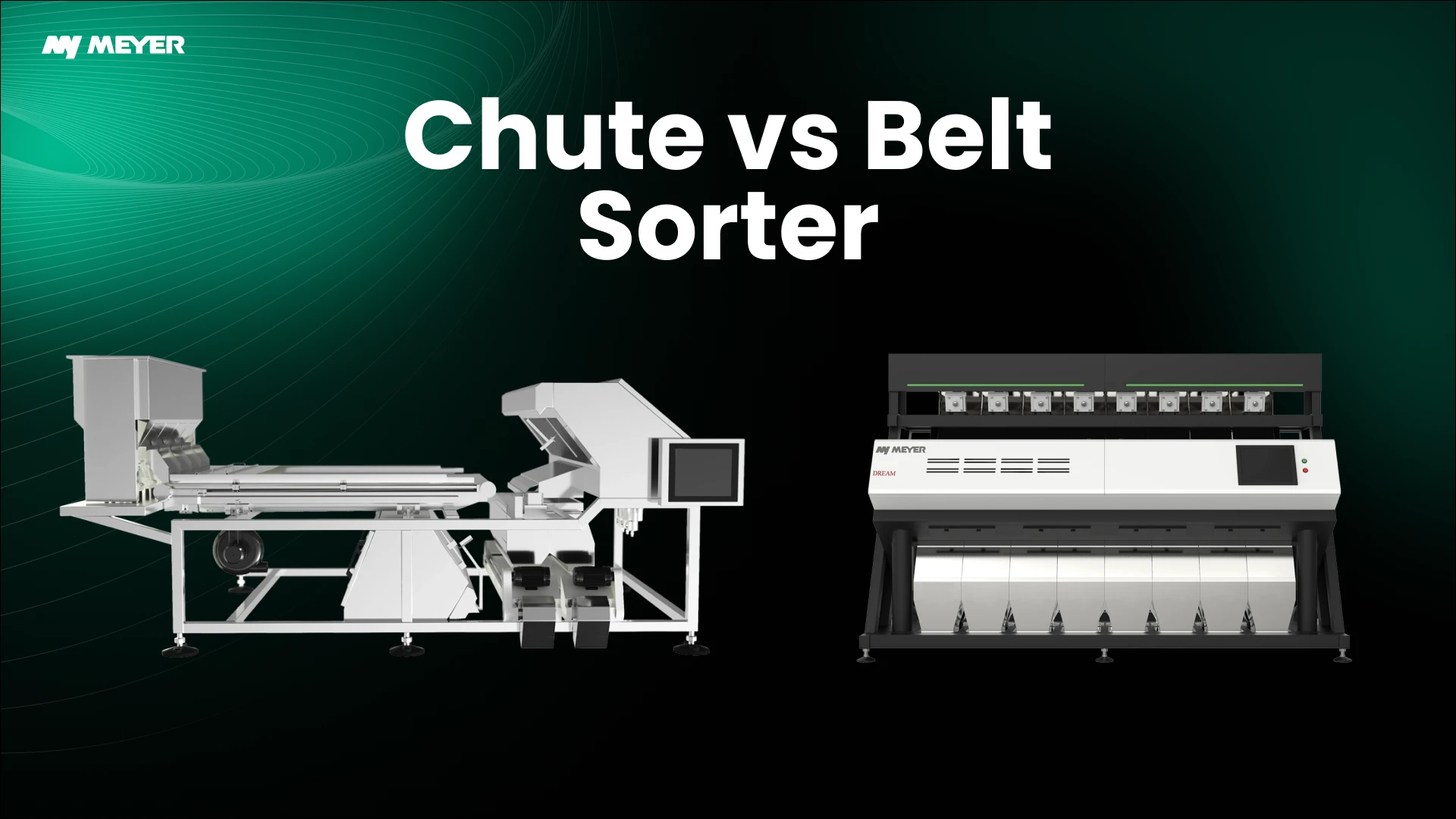

Chute Optical Sorters

Chute-based systems utilize gravity to move products down a specially designed slide or chute. As materials fall through the inspection zone, they are scanned by cameras. Upon detection of items meeting rejection criteria, precisely-timed ejectors activate to deflect unwanted materials into separate channels, while acceptable products continue their natural trajectory.

Belt Optical Sorters

Belt sorters transport products on a conveyor belt through the inspection zone at a controlled speed. Cameras mounted above and below the belt analyze the products as they move. When unwanted items are detected, air jets or mechanical devices eject them from the product stream. The belt provides stable, controlled product handling throughout the sorting process.

| Feature | Chute Optical Sorters | Belt Optical Sorters |

| Working Principle | Uses gravity to slide products down a chute; sorted using air jets. | Products move on a conveyor belt; sorted by ejectors or mechanical devices. |

| Speed and Throughput | Processes 30 kg – 3,5 tons/hour per chute. | Processes 30 kg – 7 tons/hour per belt width. |

| Product Handling | Suitable for robust, uniform items like grains and nuts, but also various types of polymers. | Ideal for fragile or irregular items like fresh produce and processed foods. |

| Accuracy and Precision | Accuracy of 95 – 99,99%, may be affected by product type and contamination. | Accuracy of 97 – 99,99%, with stable product presentation enabling precision. |

| Best Applications | Grain, coffee, nuts, plastic pellets and flakes, mining materials. | Fruits, vegetables, processed foods, metal, glass. |

| Maintenance Needs | Low mechanical complexity; fewer moving parts | Regular belt maintenance; higher maintenance costs. |

| Energy Efficiency | More energy-efficient due to simpler mechanics. | Higher power consumption due to belt drives. |

| Initial Cost | Lower due to simpler design. | Higher due to the complexity of the belt system. |

| Operating Costs | Lower due to minimal energy and maintenance needs. | Higher due to belt replacement and power usage. |

| Space Requirements | Compact design. | Larger space requirements. |

Key Differentiating Factors

Speed and Throughput

- Chute Sorters: Generally achieve higher throughput rates due to gravity-assisted movement and the ability to handle multiple parallel product streams.

- Belt Sorters: Typically operate at lower speeds due to belt movement limitations

Product Handling

- Chute Sorters: Better suited for uniform, robust products that can withstand sliding and falling without damage. They work well with grains, nuts, and similar dry commodities.

- Belt Sorters: Provide gentler handling, making them ideal for delicate or irregularly shaped products like fresh produce, processed foods, or fragile materials.

Accuracy and Precision

- Chute Sorters: best suited for small, uniformly sized materials. They may struggle with larger or irregularly shaped items, though modern systems achieve impressive accuracy rates of 95 – 99,99%.

- Belt Sorters: Generally achieve higher accuracy (97 – 99,99%) due to stable product presentation and controlled movement, allowing for more precise imaging and sorting decisions.

Application-Specific Considerations

Best Applications for Chute Sorters

- Bulk grain sorting

- Coffee bean processing

- Nut sorting

- Plastic pellet and flakes sorting

- Mining and mineral processing

Best Applications for Belt Sorters

- Fresh and frozen fruit and vegetable sorting

- Processed food inspection

- Recycling material separation (metal, glass, rubber)

- Premium product sorting where gentle handling is crucial

- Complex sorting tasks requiring multiple criteria

Maintenance and Operational Factors

Chute Sorters

- Lower mechanical complexity due to fewer moving parts

- Reduced maintenance requirements

- Higher energy efficiency

- More compact footprint

Belt Sorters

- Regular belt maintenance and replacement needed

- Higher power consumption due to belt drive systems

- Larger floor space requirements

- More flexible for product changeovers

Cost Considerations

Initial Investment

- Chute Sorters: Generally lower initial cost due to simpler mechanical design

- Belt Sorters: Higher initial investment due to belt system and associated components

Operating Costs

- Chute Sorters: Lower energy consumption and maintenance costs

- Belt Sorters: Higher ongoing costs due to belt replacement and increased power usage

Making the Right Choice

The selection between chute and belt optical sorters should be based on:

- Product characteristics (size, shape, fragility)

- Required throughput rates

- Accuracy requirements

- Available floor space

- Budget constraints

- Maintenance capabilities

- Product changeover frequency

Organizations should carefully evaluate these factors and consider conducting trials with sample products before making a final decision.