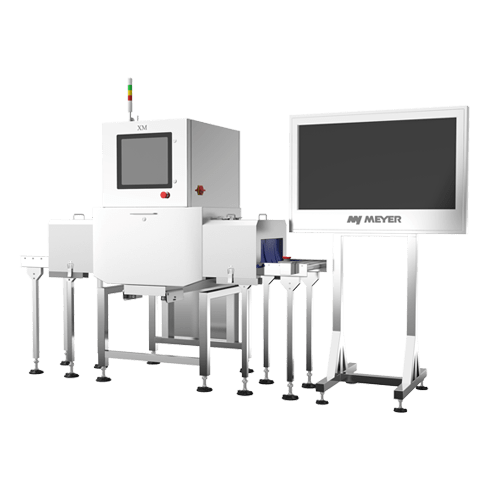

X-RAY DETECTOR

PRODUCT

X-Ray XM ultra HD

Ultra HD X-Ray detector

• Widely used in fishbone, milk powder, meat, nutrition powder

• The device is mainly aimed at high-precision detection requirements. The sensor is 0.1mm and the highest visual accuracy is 0.05mm.

• Using a special image processing algorithm it achieves very good results of detecting fishbone and bone.

Material removal types on XM X-ray machine:

• Blowing: Products in packages and low-density blocks. Used for high-speed removal for small packed materials whose weight is less than 100 g (e.g. chocolate bar). Suitable for use in high-efficiency production lines.

Swing Arm: Used to remove the impurities in medium and small packages with single lane of feed, with high accuracy and fast removal speed per unit time. Suitable for customers with fast conveyor line.

Referred material size:

50mm ≤ length ≤300mm,

50mm ≤ width ≤ 300mm,

Box Pack: 30mm ≤ thickness ≤ 250mm,

Bag Pack: 25mm ≤ thickness ≤ 150mm.

• Ejector: Suitable for impurity removal of bulk, unpackaged materials. The rejection rate of foreign materials is over 99%. With using high frequency ejectors loss of good material is minimized

• Turning removal: Used for small package. The accuracy is the highest. The capacity per unit time is larger than the use of a pushing board.

• Pushing board: Large package inspection products with a single feed stream for large packages or packing box. Referred material size:

150 mm ≤ length ≤ 300 mm,

10 mm ≤ thickness ≤ 150 mm

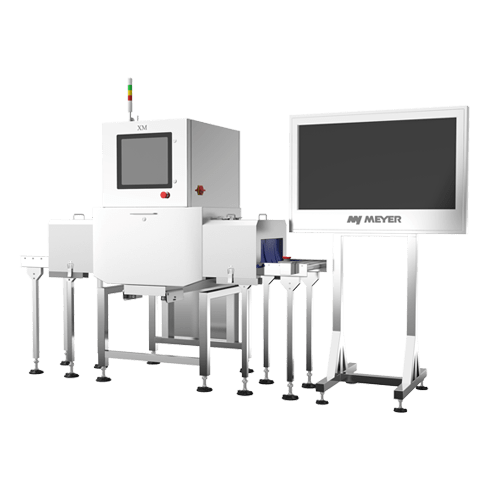

PRODUCT

X-Ray XM ultra HD

Ultra HD X-Ray detector

• Widely used in fishbone, milk powder, meat, nutrition powder

• The device is mainly aimed at high-precision detection requirements. The sensor is 0.1mm and the highest visual accuracy is 0.05mm.

• Using a special image processing algorithm it achieves very good results of detecting fishbone and bone.

Material removal types on XM X-ray machine:

• Blowing: Products in packages and low-density blocks. Used for high-speed removal for small packed materials whose weight is less than 100 g (e.g. chocolate bar). Suitable for use in high-efficiency production lines.

Swing Arm: Used to remove the impurities in medium and small packages with single lane of feed, with high accuracy and fast removal speed per unit time. Suitable for customers with fast conveyor line.

Referred material size:

50mm ≤ length ≤300mm,

50mm ≤ width ≤ 300mm,

Box Pack: 30mm ≤ thickness ≤ 250mm,

Bag Pack: 25mm ≤ thickness ≤ 150mm.

• Ejector: Suitable for impurity removal of bulk, unpackaged materials. The rejection rate of foreign materials is over 99%. With using high frequency ejectors loss of good material is minimized

• Turning removal: Used for small package. The accuracy is the highest. The capacity per unit time is larger than the use of a pushing board.

• Pushing board: Large package inspection products with a single feed stream for large packages or packing box. Referred material size:

150 mm ≤ length ≤ 300 mm,

10 mm ≤ thickness ≤ 150 mm