X-ray inspection

The safety and quality of food products are a basic requirement in the food producers’ market.

MEYER x-ray inspection systems are used to ensure the highest standards of products both in the production of food products and other industries.

X-ray detectors effectively detect and eliminate foreign bodies such as glass, stones, plastics, metals, rubber, bones, and other contaminants and product defects.

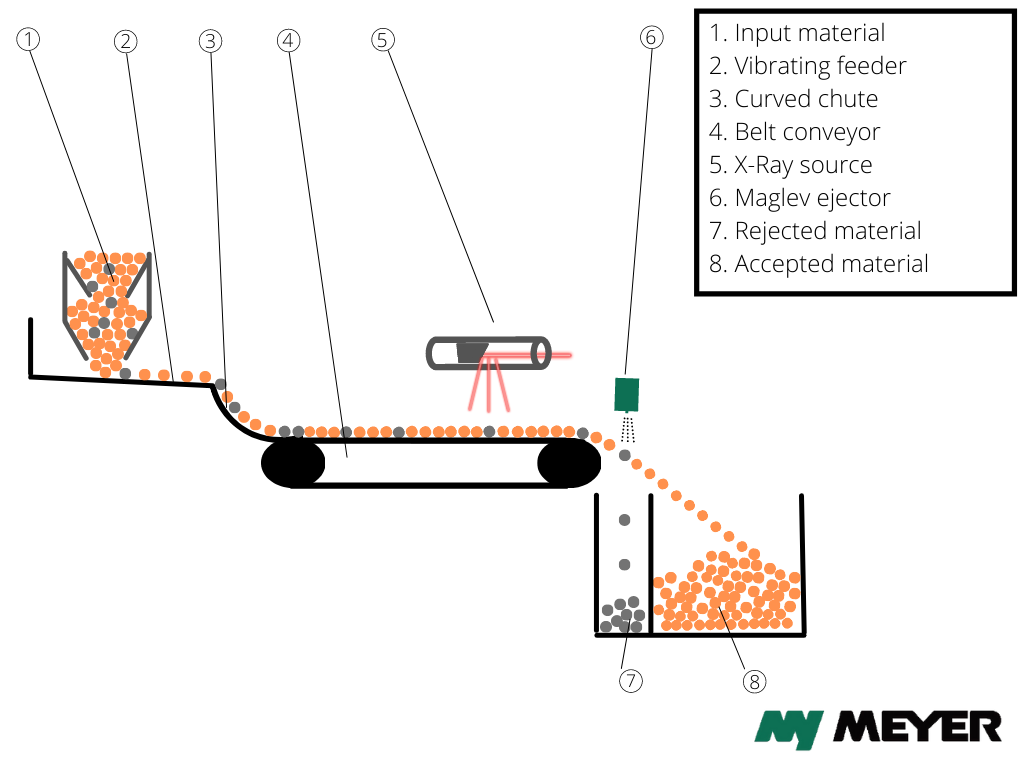

X-ray detectors consist of a conveyor belt that feeds material to the X-ray detection zone and then, after analyzing the product, to the unacceptable material removal zone.

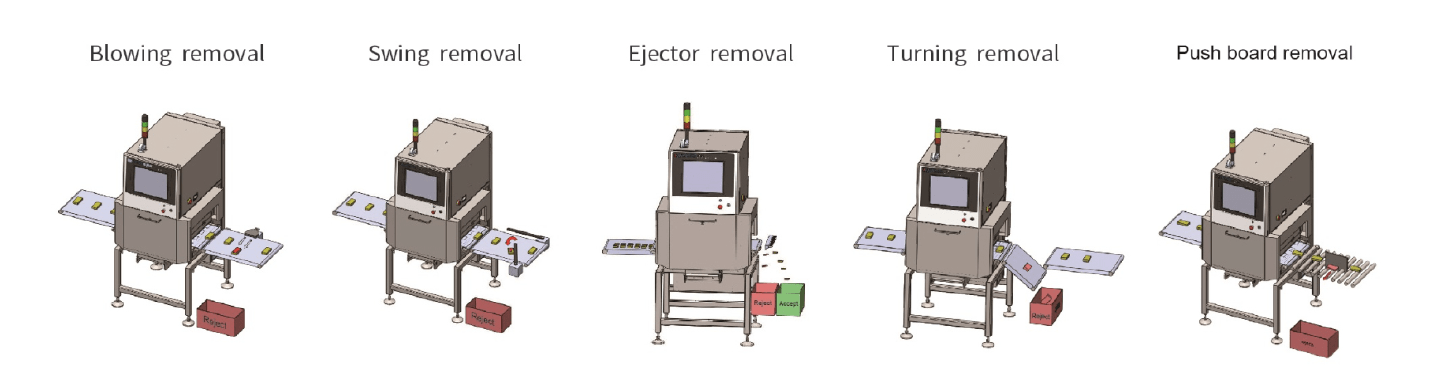

The MEYER X-Ray machines have different solutions for the removal of foreign materials, depending on the type, size and weight of the product to be inspected and the production needs. After detecting product defects, inspection devices can remove them by blowing, using a ejector, swing arm, ejectors, pushing board and turning removal, and can also stop the inspection tape and display an X-ray abnormality message.

X-ray inspection

The safety and quality of food products are a basic requirement in the food producers’ market.

MEYER x-ray inspection systems are used to ensure the highest standards of products both in the production of food products and other industries.

X-ray detectors effectively detect and eliminate foreign bodies such as glass, stones, plastics, metals, rubber, bones, and other contaminants and product defects.

X-ray detectors consist of a conveyor belt that feeds material to the X-ray detection zone and then, after analyzing the product, to the unacceptable material removal zone.

The MEYER X-Ray machines have different solutions for the removal of foreign materials, depending on the type, size and weight of the product to be inspected and the production needs. After detecting product defects, inspection devices can remove them by blowing, using a ejector, swing arm, ejectors, pushing board and turning removal, and can also stop the inspection tape and display an X-ray abnormality message.

- Blowing: Products in packages and low-density blocks. Used for high-speed removal for small packed materials whose weight is less than 100 g (e.g. chocolate bar). Suitable for use in high-efficiency production lines.

- Swing Arm: Used to remove the impurities in medium and small packages with a single lane of feed, with high accuracy and fast removal speed per unit time. Suitable for customers with a fast conveyor line.

Referred material size:

50mm ≤ length ≤300mm,

50mm ≤ width ≤ 300mm,

Box Pack: 30mm ≤ thickness ≤ 250mm,

Bag Pack: 25mm ≤ thickness ≤ 150mm. - Ejector: Suitable for impurity removal of bulk, unpackaged materials. The rejection rate of foreign materials is over 99%. With using high-frequency ejectors loss of good material is minimized

- Turning removal: Used for a small package. The accuracy is the highest. The capacity per unit time is larger than the use of a pushing board.

- Pushing board: Large package inspection products with a single feed stream for large packages or packing boxes. Referred material size:

150 mm ≤ length ≤ 300 mm,

10 mm ≤ thickness ≤ 150 mm.

How to remove defects or packaged products containing foreign materials on MEYER X-ray machines:

- Blowing: Products in packages and low-density blocks. Used for high-speed removal for small packed materials whose weight is less than 100 g (e.g. chocolate bar). Suitable for use in high-efficiency production lines.

- Swing Arm: Used to remove the impurities in medium and small packages with a single lane of feed, with high accuracy and fast removal speed per unit time. Suitable for customers with a fast conveyor line.

Referred material size:

50mm ≤ length ≤300mm,

50mm ≤ width ≤ 300mm,

Box Pack: 30mm ≤ thickness ≤ 250mm,

Bag Pack: 25mm ≤ thickness ≤ 150mm. - Ejector: Suitable for impurity removal of bulk, unpackaged materials. The rejection rate of foreign materials is over 99%. With using high-frequency ejectors loss of good material is minimized

- Turning removal: Used for a small package. The accuracy is the highest. The capacity per unit time is larger than the use of a pushing board.

- Pushing board: Large package inspection products with a single feed stream for large packages or packing boxes. Referred material size:

150 mm ≤ length ≤ 300 mm,

10 mm ≤ thickness ≤ 150 mm.